Hi All,

I'm new here but a friend told me I should put in my 2 cents worth so I signed up. I look forward to contributing on these types of discussions and hopefully sharing some experience of load cells,

hoist control and general rigging.

Chain motors are fine for

overhead lifting. This is proven and generally accepted the world over, provided it is done properly of course. I have seen some winches in

theatre use that were sourced from the local surplus/auto parts stores...

point is, it has to be done correctly to be safe and this applies to winches,

chain hoist, hardware

etc..

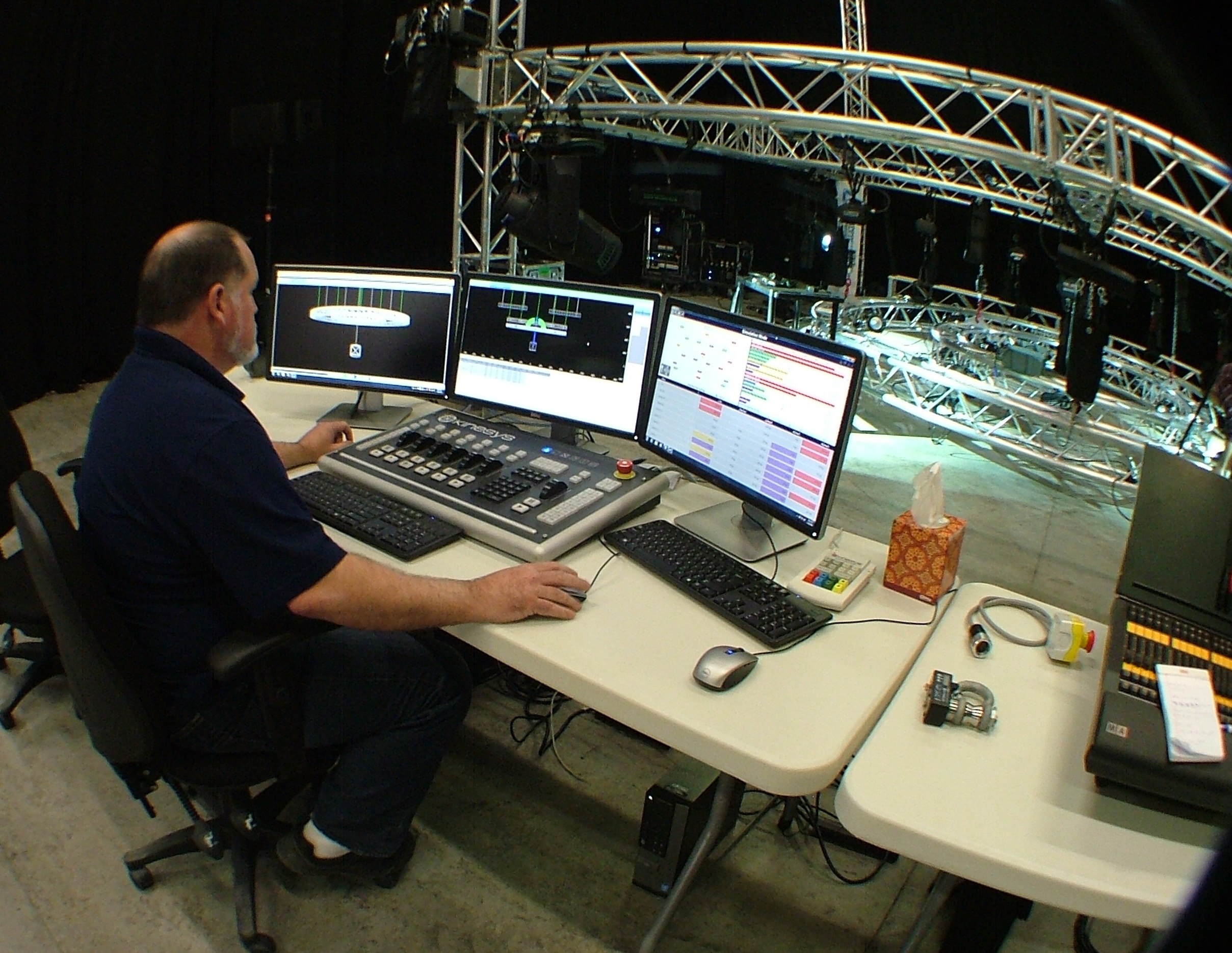

Kinesys offers synchronised fixed-speed

hoist systems with

load cell options as well as our well-known variable speed systems (including zero-speed offerings) which can also be monitored by our load cells.

We do have an office and training facility near Atlanta as mentioned above with a warehouse for parts

stock, sales

stock, training and demos. When I figure out how to post photos I will.

If you don't know the Kinesys DigiHoist

line, Libra load cells or the Kinesys brand in general; we manufacture intelligent

chain hoist controls (variable or fixed speed) with additional features such as

hoist positional

feedback,

hoist present status, limit status, running direction,

phase correction and load sensing (aka load cells). These systems are ideal where the true balance of the load is indeterminate over multiple hoists, or if each

hoist’s safe range of operation is dependent on the adjacent

hoist(s) taking their proportional amount of the load. DigiHoist systems are also programmable so defined allowable loads can be set,

preset positions can be achieved and even show cues for movement during a show can be run.

We work with most major

hoist brands (fixed speed and variable) including CM

Lodestar, Chain Master, Pointman, EXE, GIS, Liftket and more. I hope this is helpful and please feel free to ask any questions. You can contact us directly as well should you need advice, info or pricing.

[email protected]