jeffspec

Member

hi.

my name is jeff. i direct plays in unusual places. i live in new york.

my current project is unusual for me because it demands a large set piece. to be exact, i have to create a life-like drive-in movie screen.

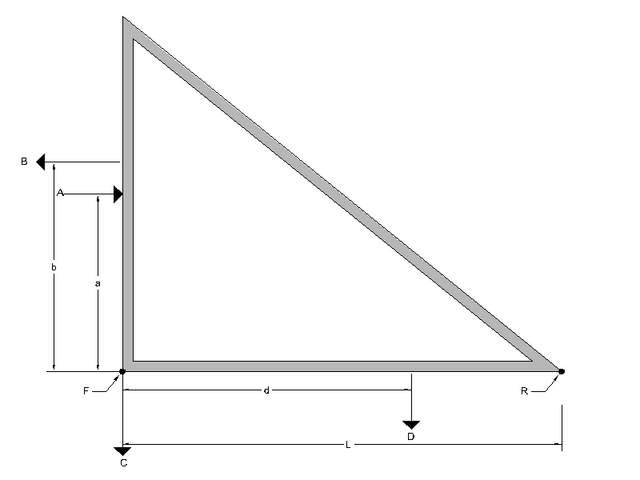

it wouldnt be such a huge deal if i could build it like a real screen. unfortunately i can not anchor into anything, which means i need to build a 40-foot wall with a lot of sandbags.

does anyone have any suggestions off the bat? the dimensions are 28 tall by 40 wide. i can make the supporting truss at the back at any angle. also, i can not guy line it from the top: the screen has to be freestanding.

could i get away with building dozens of flats and zipping them together, then propping them up with oversized jackstands? seems crazy to me.

any pointers greatly appreciated. i guess what i'm asking for more than anything is: can anyone point me to a guide for making a 30 x 40 foot wall?

thanks!

j

my name is jeff. i direct plays in unusual places. i live in new york.

my current project is unusual for me because it demands a large set piece. to be exact, i have to create a life-like drive-in movie screen.

it wouldnt be such a huge deal if i could build it like a real screen. unfortunately i can not anchor into anything, which means i need to build a 40-foot wall with a lot of sandbags.

does anyone have any suggestions off the bat? the dimensions are 28 tall by 40 wide. i can make the supporting truss at the back at any angle. also, i can not guy line it from the top: the screen has to be freestanding.

could i get away with building dozens of flats and zipping them together, then propping them up with oversized jackstands? seems crazy to me.

any pointers greatly appreciated. i guess what i'm asking for more than anything is: can anyone point me to a guide for making a 30 x 40 foot wall?

thanks!

j