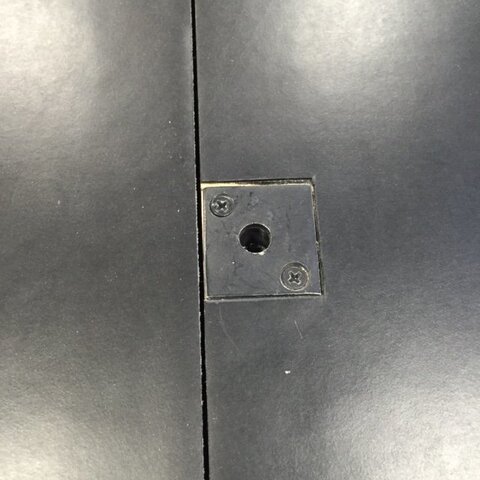

I am assuming this is a pretty simple question, but I can't find any tutorials on how to use coffin locks with a standard platform! I was looking specifically at Rosebrand's model but am open for suggestions.

Do you simply cut a notch out of the top of the plywood on the edge and screw it to the 2x4 that is exposed? Is there a better way?

Thanks!

Do you simply cut a notch out of the top of the plywood on the edge and screw it to the 2x4 that is exposed? Is there a better way?

Thanks!