So I'm building a lighting fixture that involves a bunch of bare 100w light bulbs. I've got 1.2k dimmers, so I'm looking to build several section with 11 100w bulbs. I want to wire them as a parallel circuit. What gauge wire do I need to use? The branches of the main line, can they be just regular zipline (they will go from the main to an individual 100w bulb). Also, do I need a ground?

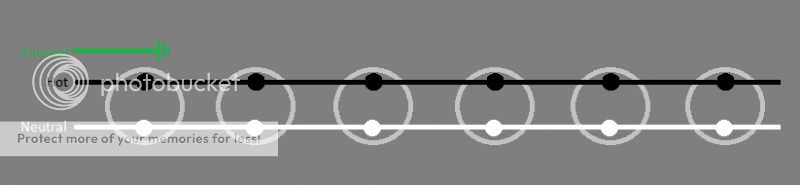

Here is a basic sketch(http://i.imgur.com/t1ARclL) (I messed up the neutral a bit on the link from the source to the first junction) and the sockets I have.(lights - Imgur)

I have the bulbs(cheap 100w from amazon), and have purchased a few sockets to build a proof of concept, but have not purchased any wire yet.

I'm usually a wrench jockey, this is all a little foreign to me. Any help would be appreciated.

Here is a basic sketch(http://i.imgur.com/t1ARclL) (I messed up the neutral a bit on the link from the source to the first junction) and the sockets I have.(lights - Imgur)

I have the bulbs(cheap 100w from amazon), and have purchased a few sockets to build a proof of concept, but have not purchased any wire yet.

I'm usually a wrench jockey, this is all a little foreign to me. Any help would be appreciated.