You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Design Home Made GOBOS

- Thread starterccm1495

- Start date

Can't do anything too fancy, but aluminum pie pans work. I've made all sorts of things from custom shapes to "realistic stars." For the stars I just used a sewing needle to poke holes. I've also made my own iris gobos using a drill press and hole saw. Make sure you sandwich the aluminum between two pieces of wood and screw them together real tight so the aluminum can't spin.

-Tim

-Tim

Okay, I'll start.

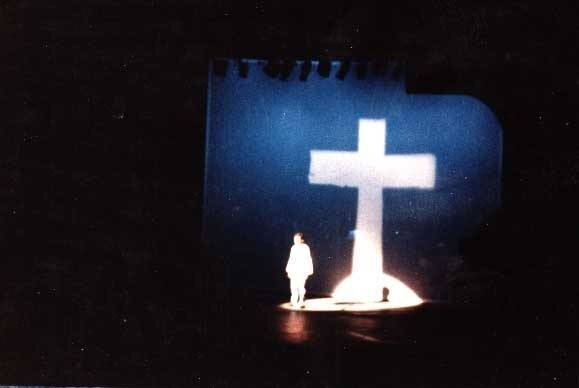

Here is the only cut-out-of-a-pie-plate gobo I've ever been happy with. (Give me a break, the not-perfect look was part of the design concept. And it was in a Kliegl 1355, IIRC.)

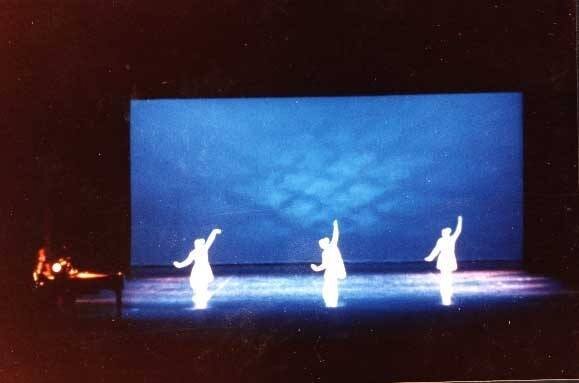

The next picture is/was one of my favorite tricks

using radiator grating as a nondescript break-up.

Search CB for homemade gobos for lots of good threads, including a recent one on acid etching. See also the collaborative article DIY Gobos.

Here is the only cut-out-of-a-pie-plate gobo I've ever been happy with. (Give me a break, the not-perfect look was part of the design concept. And it was in a Kliegl 1355, IIRC.)

The next picture is/was one of my favorite tricks

using radiator grating as a nondescript break-up.

Search CB for homemade gobos for lots of good threads, including a recent one on acid etching. See also the collaborative article DIY Gobos.

Last edited:

gcpsoundlight

Active Member

Soft drink cans work well too....

I have used Pie tins but have switched to disposable sheet pans since you can get more out of them and they are cheap as well. I just smash them flat at the bumps. I am also done acid etching. Where as you print onto the metal then take acid and burn away the "ink less" parts. You can get much crisper designs using this method though it has its dangers (can cause burns/fumes). I didnt have any issues and got the acid from Radio Shack and the metal from Home Depo.

Also done the disposable cookie sheet thing--just from the local grocery store. I have cut text in one before, but nothing too long or too fancy. I recommend using a sharp Exacto, and use multiple passes where you want to cut. You'll get cleaner lines, have smoother curves, and your knife won't accidentally skate across the material. Needless to say, if you're using this material, be really sure that you haven't got a hot spot before you insert the gobo. Otherwise much wailing and gnashing of teeth.

Also (back in the day) did the acid resist method on brass shim stock, but that was back when you didn't have the kind or price and selection that is available now. I'll try to take some shots later.

Also (back in the day) did the acid resist method on brass shim stock, but that was back when you didn't have the kind or price and selection that is available now. I'll try to take some shots later.

So we've all made gobos with "pie pans".

Speak for yourself. After having to do maitenance on instruments that used nothing but pie pan gobos I swore I'd never use them.

Speak for yourself. After having to do maitenance on instruments that used nothing but pie pan gobos I swore I'd never use them.

Come on Grog, you never made just one?

I hate them too and I've got a pretty good collection of purchased gobos to rely on. But just last year I had a show that needed a bunch of Irises for. Not having enough I used pie tin gobos.

By the way I found these little "chicken pot pie" sized pans. The bottom of the pan was almost the perfect size for a gobo. It was fairly thin aluminum so I wouldn't recomend using them for more than a few minutes at a time. I cut them with Exacto knifes.

The next picture is/was one of my favorite tricks

using radiator grating as a nondescript break-up.

A favorite of mine as well. I normally go for the triangle pattern, but I've gone with another style or two if I find an interesting one.

So we've all made gobos with "pie pans".

What sort of "pie pan" do you use?

What's your favorite tool to cut it with?

My "pie pan" is aluminum sheet stock.

I cut them to size with tin snips. After which I will go at them with either snips, drill, or the dermal to get the design I want. Not for anything that needs to be spot on

David Ashton

Well-Known Member

I too used litho plates, there was a print shop next to the theatre who would give them away, my first ever job in pro theatre was cutting up these plates and bashing hundreds of holes in them with a chipping hammer to make "dekkle" gobos to fit in Strand Patt 23s for The Australian Ballet production at our theatre and it's still a vey cheap but effective effect, even with old and seldom used profiles.

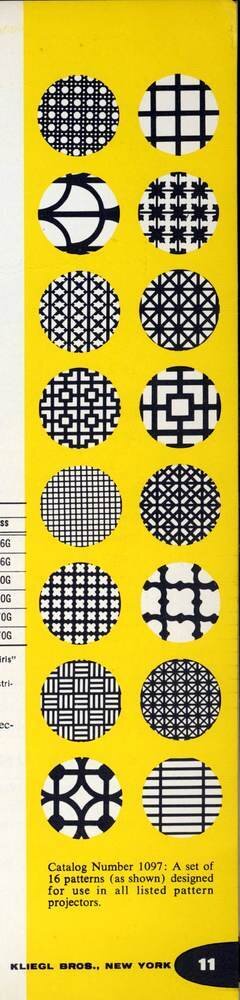

Somewhat humbling to think that people were using radiator grating as gobos going back to at least 1957, and likely to the beginning of the ERS.A favorite of mine as well. I normally go for the triangle pattern, but I've gone with another style or two if I find an interesting one. ...

Kliegl Bros. Catalog#T-61, 1957.

Good idea! My (former) junior high had a CNC machine capable of working with soft metal and I never thought I could use it for gobos.I've recently discovered that the school has a CNC machine down in the Industrial Tech wing. I'm salivating at the idea of on-demand custom gobos on the cheap.

I've recently discovered that the school has a CNC machine down in the Industrial Tech wing. I'm salivating at the idea of on-demand custom gobos on the cheap.

Cheater...

TheGuruat12

Member

What kind of acid will work with the pie pan?

Similar threads

- Replies

- 9

- Views

- 635

- Replies

- 2

- Views

- 368

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)