OK Here goes. I am new to the site (and chats in general) but need some tech help with a sticky set design it's a fairly long read:

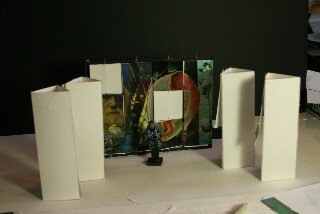

We need to create a mural as a major scenic element – it will be revealed as the play progresses. (The end units might be periactoi, but) the center US wants to be a wall of panels – each panel 4’ w. x 12’ h (maybe 12 or 16’w. x 12’ h. in all)., made up of 3 smaller 4’x 4’ panels stacked on top of one another(vertical). These 4x4 want to rotate on a central axis, each independently (to reveal the mural parts), and some will return to it’s original position. Sort of like Laugh-In but not doors. Panels will need a stop of some kind, and this is one piece of hardware I need, swivel or bushing with a stop or pause.

One rotating idea is for a central aluminum pipe with a sleeve over it, integral to each panel.(I’m thinking of the panels as being maybe a sandwich of 1” Styrofoam sandwiched in ¼” Gatorfoam, pipe running down the middle.) The central pipe will need vertical stops, maybe this bushing, to keep the panels in position. We use a lot of Speedrail fittings and alum pipes for touring screens and sets, but I don’t know if they would hold the pipes/panels square enough.

The kicker is that this needs to tour (but not run-outs). Any ideas? Thanks!

We need to create a mural as a major scenic element – it will be revealed as the play progresses. (The end units might be periactoi, but) the center US wants to be a wall of panels – each panel 4’ w. x 12’ h (maybe 12 or 16’w. x 12’ h. in all)., made up of 3 smaller 4’x 4’ panels stacked on top of one another(vertical). These 4x4 want to rotate on a central axis, each independently (to reveal the mural parts), and some will return to it’s original position. Sort of like Laugh-In but not doors. Panels will need a stop of some kind, and this is one piece of hardware I need, swivel or bushing with a stop or pause.

One rotating idea is for a central aluminum pipe with a sleeve over it, integral to each panel.(I’m thinking of the panels as being maybe a sandwich of 1” Styrofoam sandwiched in ¼” Gatorfoam, pipe running down the middle.) The central pipe will need vertical stops, maybe this bushing, to keep the panels in position. We use a lot of Speedrail fittings and alum pipes for touring screens and sets, but I don’t know if they would hold the pipes/panels square enough.

The kicker is that this needs to tour (but not run-outs). Any ideas? Thanks!