I've been at least peripherally involved with lighting issues for more than 30 years in my experience as a thespian, musician, sound engineer and stage manager, but I must confess my ignorance and ask the following question: when dimming lights with a conventional dimmer pack (Leviton N6000 for example) how much power is being used at various points in the "dimming curve"? In other words, if a 1KW lamp at full power is pulling (approx) 10 amps, what is it pulling when dimmed 50%? 75% 25%? Is it a straight one-to-one correspondence or is there another formula? I do one-nighters all over the place and I always worry about having adequate power for what I would like to do.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power realities

- Thread starterfoh1217

- Start date

gcpsoundlight

Active Member

Hi.

First of all, you should understand how a dimmer works. It does not vary (in most cases) the peak voltage, but the RMS (Root Mean Square) Voltage, by using a number of FET's (Field Effect Transistor) cutting the sine wave of the mains off at varoius points along the cycle.This is why when you plug in a lamp that does not draw much power, that the lamp can still be lit at 0% ie: Fairy Lights etc. My feeling, having not had this problem before, is that the current won't vary, but the RMS Voltage WILL.

As long as your lamps are not rated at more than the maximum output of the dimmer, then you should be fine.

First of all, you should understand how a dimmer works. It does not vary (in most cases) the peak voltage, but the RMS (Root Mean Square) Voltage, by using a number of FET's (Field Effect Transistor) cutting the sine wave of the mains off at varoius points along the cycle.This is why when you plug in a lamp that does not draw much power, that the lamp can still be lit at 0% ie: Fairy Lights etc. My feeling, having not had this problem before, is that the current won't vary, but the RMS Voltage WILL.

As long as your lamps are not rated at more than the maximum output of the dimmer, then you should be fine.

I do one-nighters all over the place and I always worry about having adequate power for what I would like to do.

As I answer this. I'm thinking this might be a trick question for the ETCP test !.

The simple answer is you calculate the "demand" load - I.E., the wattages of all the fixtures when operating at full intensity, divided by the voltage at the lamp, to determine the total number of amps required, then divide by the number of phases for the feed, to determine the feed requirement.

You don't really ever need to calculate the lamp loads at various points in the dimming cycle, as the only real thing you are worried about is maximum draw, which is at full output.

The lighting paperwork program - Lightwright, is typical of software that does this for you, and this is the formula the program uses.

FWIW, I believe it is against typical electrical codes to provide for feeder systems based on "never running the lamps at full". I believe that you must take into account full intensity as maximum load.

I don't think his question is intended to be based on installs and regarding code, but rather if you have a 15A Max on a shoebox dimmer with (4) dimmers in it, each rated individually for 10A, and you put 7A on each dimmer, how many lights can you have on at the same time if they were all dimmed down to 65% or something like that.

I forget the actual numbers, but unfortunately it's not a linear relationship. The console might have the dimmer a 750w fixture is connected to at 25% but your load is a lot higher than 25% of 750w. Dimming down higher wattage lights so that you can turn on more of them does not work well at all because you don't really save that much power by dimming down.

If you find yourself constantly worrying about having enough power to do you job, find more power or use lower wattage lamps.

I'll rely on someone else to come up with the exact figures on when you dim down a certain amount, how the load is actually affected.

I don't think his question is intended to be based on installs and regarding code, but rather if you have a 15A Max on a shoebox dimmer with (4) dimmers in it, each rated individually for 10A, and you put 7A on each dimmer, how many lights can you have on at the same time if they were all dimmed down to 65% or something like that.

.

The answer remains that you can't calculate the power supply, and it don't matter if it's permanent, temporary, code compliant or not, on a dimmed down load.

As a practical matter, you have to calculate to full load just in case somebody forgets and runs the faders at full.

And as I recall my past experiences as LD at the Lincoln Center Out-of-Doors festival (early 80's), in NYC, the plot had way over 100 amps per phase demand load, which was our supply limit. We had the TTI 24ch 2 scene console labeled at each fader with the amperage load on ea. dimmer - "30", "40", 30", "35", etc....

One of the visiting LD's was Allen Lee Huges, who came in with a dance company for a one-off, accompanied by a pile of 2-scene preset cue sheets he had prepared. When I explained that you had to add up the amperage of the faders to not exceed 100 in any preset, he had one of those Alices Restaurant moments - looked at the amperage numbers, looked at his pile of cues, looked back at the amperage numbers and quickly realized that his "47 eight by ten" cue sheets were worthless. He ran the show manually on the fly. Looked great.

Much as I hate to, I have to quote wikipedia on this:

Wikipedia: Dimmer

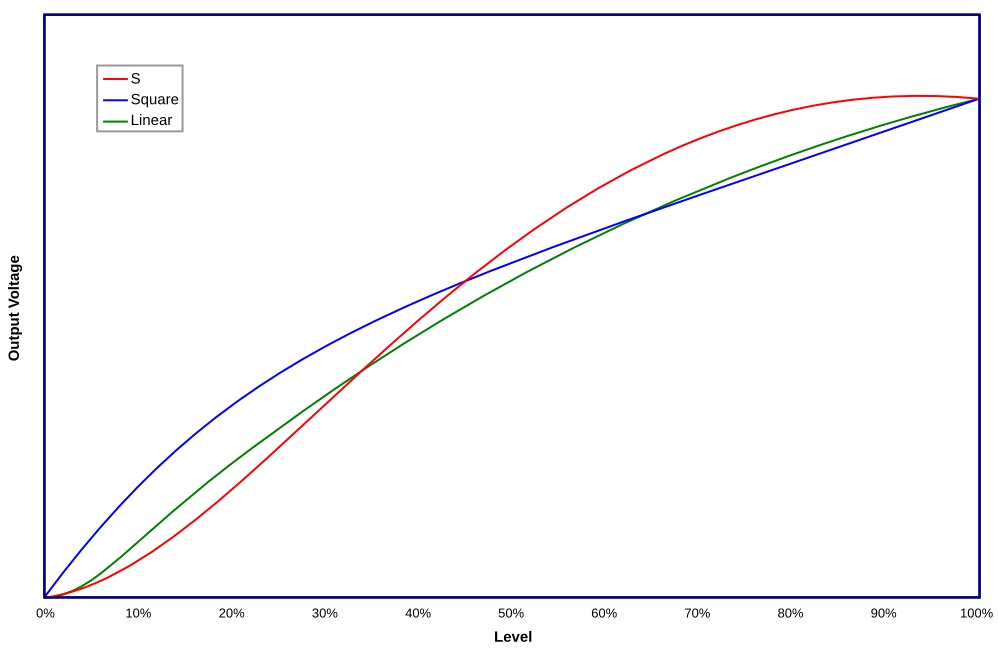

The three most-used curves are linear, square, and S.

Note that most inexpensive shoebox dimmers have horrible curves. See Dimmer voltage experiment for one example. See also the thread: http://www.controlbooth.com/forums/lighting/9449-dimmer-profiling-avoid-over-wattage.html, and http://www.controlbooth.com/forums/lighting/8515-shoebox-dimmer-question.html.

Agree with the sentiments above that this is a dangerous game to play. Risking having a dimmer pack failure or a circuit breaker trip during the performance just isn't worth the reward. In cases where power is limited, use fewer or lower wattage lamps.

Wikipedia: Dimmer

The three most-used curves are linear, square, and S.

Note that most inexpensive shoebox dimmers have horrible curves. See Dimmer voltage experiment for one example. See also the thread: http://www.controlbooth.com/forums/lighting/9449-dimmer-profiling-avoid-over-wattage.html, and http://www.controlbooth.com/forums/lighting/8515-shoebox-dimmer-question.html.

Agree with the sentiments above that this is a dangerous game to play. Risking having a dimmer pack failure or a circuit breaker trip during the performance just isn't worth the reward. In cases where power is limited, use fewer or lower wattage lamps.

JD

Well-Known Member

Well, the thing about tungsten lamps is that the resistance changes with the temperature of the filament. This is why a cold lamp draws such a heavy inrush. As the voltage goes up, the resistance goes up. It is very non-liner. As for power, always been a problem with traveling shows! I toured with a 40k show back in the late 70's and you would walk into a venue and find out all you had was a 50X2. Well, time for a quick redesign of the light plot! It can be done but it's a pain. As an LD, you then try to limit your scenes to a well balanced 10k max. In those days everything was analog so we had these things called diode matrix panels. (pictured) I must say, things are better all around these days. Still.....

STEVETERRY

Well-Known Member

Hi.

First of all, you should understand how a dimmer works. It does not vary (in most cases) the peak voltage, but the RMS (Root Mean Square) Voltage, by using a number of FET's (Field Effect Transistor) cutting the sine wave of the mains off at varoius points along the cycle.This is why when you plug in a lamp that does not draw much power, that the lamp can still be lit at 0% ie: Fairy Lights etc. My feeling, having not had this problem before, is that the current won't vary, but the RMS Voltage WILL.

As long as your lamps are not rated at more than the maximum output of the dimmer, then you should be fine.

Err...not exactly.

1. A phase control dimmer will vary the peak as well as the RMS voltage. This is because when it is turned on late in the half cycle (for a low dimmer setting), the peak voltage at that point in the sinewave is lower than at the 90 degree point.

2. Most phase control dimmers use thyristors (SCR's or Triacs) as the power handling device, not FET's as you stated.

3. The reason that most phase control dimmers can light a very low current load at 0% (like a neon lamp) is the leakage current through the thyristor and snubber network (if used).

4. The current will vary with the RMS voltage of the dimmer--lower settings=lower voltage=lower current.

5. From a practical point of view, available power should be calculated based on the connected load, not the dimmer setting. If this rule is not followed, unintended long blackouts, followed by loud cursing, can find their way into the cue sheet.

ST

David Ashton

Well-Known Member

I covered this in the preheat debate with some experimental results which are here,

"

Default Re: Preheating Conventionals?

Please consider, a 1000 watt 240 volt T19 on a dimmer{for 120v thinkers just halve all the figures} It has a cold resistance of 3.8 ohms and a hot resistance of 57.6 ohms. A typical dimmer will feed 1.65v at "0" and drive .35A putting 2.24 W into the lamp of preheat.

@ 13V you can see the barest glow in the filament and are drawing .96A and 12.6W

@30V you can see a real glow and are drawing 1.5A and 45W

at 60V you begin to get some output but at 1/4 voltage you are drawing 2A or nearly half the "full" current

@80V which is 1/3 voltage you are drawing 2.3A which is more than half the full load current and is also the point at which the dimmer starts to interact with the other dimmers on other phases.

This is why running all your dimmers at 1/3 is the worst thing you can do to your neutrals.

Now there is a benefit in Pre-heating 2k and 5k in the previous cue, in effect you are moving them up the dimmer curve, but I have experimented with lamps and the increased resistance only lasts for a few seconds with 1/2k and a couple of minutes with 2k"s.

The thermal mass of a theatre lamp has to be as low as possible to enable it to light up and dim quickly, and pre-heating is not logical, especially when all your dimmers are "leaking" a few watts of heat anyway, so by all means turn on your lights to check them but be aware you are not helping to increase their lives and are probably shortening them and wasting a hell of a lot of power in the process.

__________________

This gives you approx answer to your question but with minor variations with different curves and lamps.

Edit/Delete Message

"

Default Re: Preheating Conventionals?

Please consider, a 1000 watt 240 volt T19 on a dimmer{for 120v thinkers just halve all the figures} It has a cold resistance of 3.8 ohms and a hot resistance of 57.6 ohms. A typical dimmer will feed 1.65v at "0" and drive .35A putting 2.24 W into the lamp of preheat.

@ 13V you can see the barest glow in the filament and are drawing .96A and 12.6W

@30V you can see a real glow and are drawing 1.5A and 45W

at 60V you begin to get some output but at 1/4 voltage you are drawing 2A or nearly half the "full" current

@80V which is 1/3 voltage you are drawing 2.3A which is more than half the full load current and is also the point at which the dimmer starts to interact with the other dimmers on other phases.

This is why running all your dimmers at 1/3 is the worst thing you can do to your neutrals.

Now there is a benefit in Pre-heating 2k and 5k in the previous cue, in effect you are moving them up the dimmer curve, but I have experimented with lamps and the increased resistance only lasts for a few seconds with 1/2k and a couple of minutes with 2k"s.

The thermal mass of a theatre lamp has to be as low as possible to enable it to light up and dim quickly, and pre-heating is not logical, especially when all your dimmers are "leaking" a few watts of heat anyway, so by all means turn on your lights to check them but be aware you are not helping to increase their lives and are probably shortening them and wasting a hell of a lot of power in the process.

__________________

This gives you approx answer to your question but with minor variations with different curves and lamps.

Edit/Delete Message

Last edited:

Similar threads

- Replies

- 28

- Views

- 3K

Control/Dimming

Followspot Dimming Issues

- Replies

- 3

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)