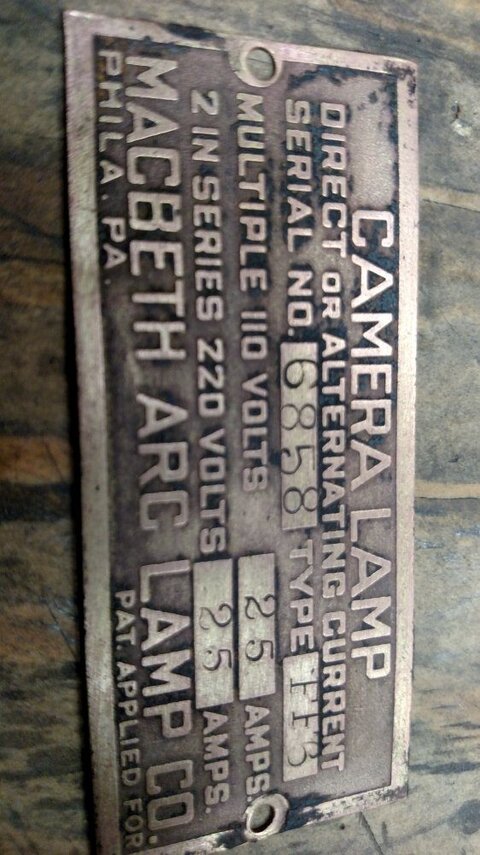

I'm tonight finally opening up the arc sustain mechanism cover to the 25Amp AC/DC Macbeth Arc wash light c.1910 at most for date... (Brass name plate it is also helps determine age.) Other lights in research with different model numbers and slightly different parts shown in photos to them area clearly later - especially given their 30 amp listing.

Looking at what is a self sustaining carbon arch mechanism on it. Looking at it, scratching head, looking further.. a... possibly variable resistance to current flow concept of electromagnet with a plate at the top of it to shunt or stop the arc when warn out... or an off switch. And I can also see a possibly a hydraulic or pneumatic cylinder that's compromised or in not knowing what it does or is, might work fine for what ever it does also attached to the gears but not wiring. That plus lots of gears and arms doing stuff and only guesses in how it all worked at this point.

The arc gap when the fixture is level is a constant not touching (self balanced) - this even before working on it - pneumatic cylinder or not a role in working or not. The balance of the arc rods is such you can touch them or bounce away. Strange for such a thing and so old. How the sustaining mechanism works???

I have a 1916 pocket sized product catalogue from a different company listing products with self sustaining arc lights.. why such things went out of existence I have no idea, nor how it works. I have other carbon arch fixtures in stock and there is knobs and levers to control / sustain the beam - this has none. It is clearly a self sustaining carbon arc.

Before I take apart to restore & perhaps make work, I need to know how it/why it works. At least at this point I have a general understanding on how the resistance coils work. - How the counter balance to the arc concept works.... no idea yet.

Looking at what is a self sustaining carbon arch mechanism on it. Looking at it, scratching head, looking further.. a... possibly variable resistance to current flow concept of electromagnet with a plate at the top of it to shunt or stop the arc when warn out... or an off switch. And I can also see a possibly a hydraulic or pneumatic cylinder that's compromised or in not knowing what it does or is, might work fine for what ever it does also attached to the gears but not wiring. That plus lots of gears and arms doing stuff and only guesses in how it all worked at this point.

The arc gap when the fixture is level is a constant not touching (self balanced) - this even before working on it - pneumatic cylinder or not a role in working or not. The balance of the arc rods is such you can touch them or bounce away. Strange for such a thing and so old. How the sustaining mechanism works???

I have a 1916 pocket sized product catalogue from a different company listing products with self sustaining arc lights.. why such things went out of existence I have no idea, nor how it works. I have other carbon arch fixtures in stock and there is knobs and levers to control / sustain the beam - this has none. It is clearly a self sustaining carbon arc.

Before I take apart to restore & perhaps make work, I need to know how it/why it works. At least at this point I have a general understanding on how the resistance coils work. - How the counter balance to the arc concept works.... no idea yet.

Attachments

Last edited: