Quillons

Active Member

Hey everyone,

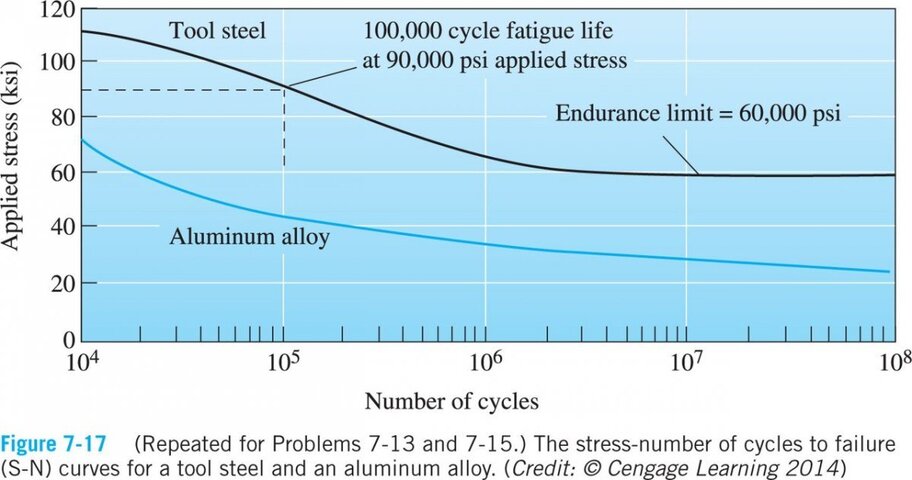

I just got out of my Metallurgy class where we were talking about (in part) fatigue in metals. We learned about a Rotating Beam Test, which "provides sinusoidal tension and compression of equal magnitude" (a test rod is forced to frown and then rotated, so that any given point on the rod goes through a cycle of tension, relaxation, compression, relaxation...). This cycle continues until the rod breaks.

For some ('minimally' loaded) steel, the rod will never break.

But for the generic aluminum alloy we were looking at, the rod will always, eventually, break.

Does aluminum truss have a rule-of-thumb lifespan? Or, because it wouldn't be loaded to anywhere near... Capacity?... Noticeable amounts?... is this something that isn't worried about?

I attached the graph if anyone wants to take a look at it.

Thanks!

I just got out of my Metallurgy class where we were talking about (in part) fatigue in metals. We learned about a Rotating Beam Test, which "provides sinusoidal tension and compression of equal magnitude" (a test rod is forced to frown and then rotated, so that any given point on the rod goes through a cycle of tension, relaxation, compression, relaxation...). This cycle continues until the rod breaks.

For some ('minimally' loaded) steel, the rod will never break.

But for the generic aluminum alloy we were looking at, the rod will always, eventually, break.

Does aluminum truss have a rule-of-thumb lifespan? Or, because it wouldn't be loaded to anywhere near... Capacity?... Noticeable amounts?... is this something that isn't worried about?

I attached the graph if anyone wants to take a look at it.

Thanks!