dpak

Active Member

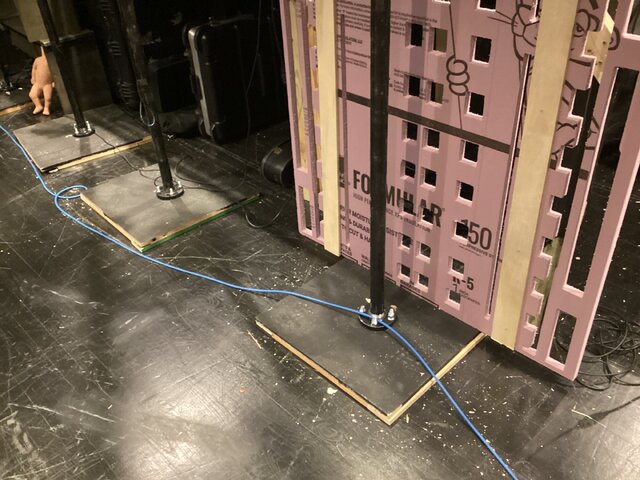

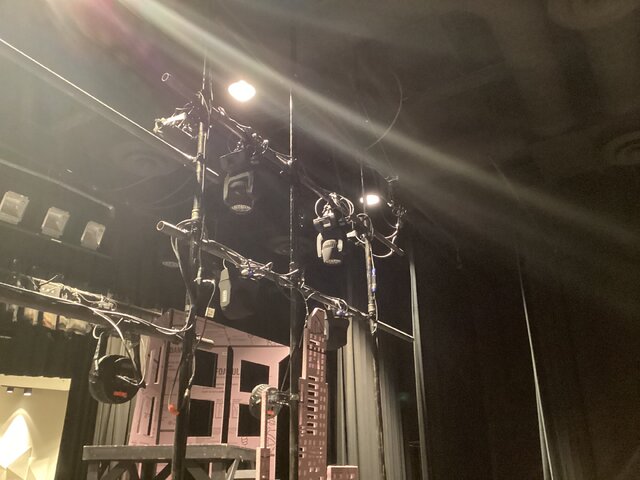

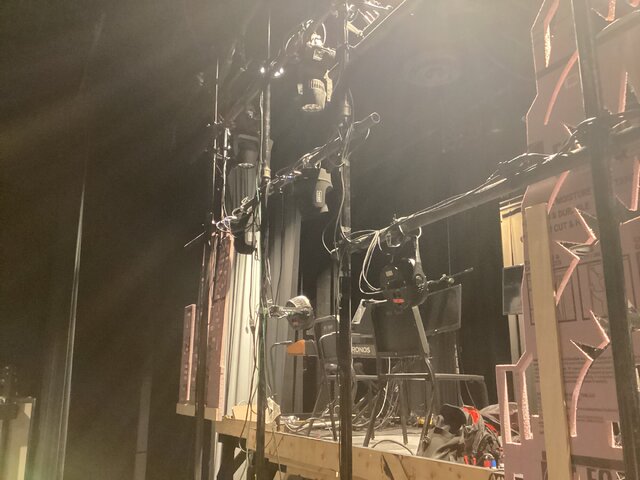

So the chorus teacher, on someone else's advice, bought a lot of schedule 40 water pipes to make a grid to hold lights (he had a connection that could get the pipes cheap). The thought was to have them on a base plate on the stage and attach them to the pipes hanging above the stage, then use cheeseboros to attach some horizontal pipes. The problem (or at least one of them) is that the pipes are 2.25 inches in diameter and not 2 inches. None of the cheeseboros he bought fit, and only my c clamps will fit around the pipe. Is possible (and advisable) to make8 hojmemade cheeseboros out of c clamps? Or are there other options to connect the pipes? Or is he just out of luck and money?