My high school theater program, while being one of the most successful, is probably the least funded program in my school. We get $3500 a year to do two plays and a musical, and we have about zero technology that the school actually owns, meaning we have to rent about 90% of the lighting and about 75% of the sound equipment - all while staying within the $3500 of course. For our musical this year, we are wanting to build a house interior that will spin around to be a street scene, and a barn interior that will spin around to be a cabin scene. We also need to have two levels in the house. What I'm thinking, is a large platform (about 14'x14' on casters, that will have a loft type platform 8' above the bottom platform, with bracing, and then just basic flats for the backdrop between the two levels. We need two of these (one for the house and one for the barn), and they will spin around to have a different scene on the backside of the set. There will only be one person on the top platforms at any time. Are there any suggestions as far as materials, designs, safety, budget, etc.? We'd like to do it with about $350-400. Thank you!

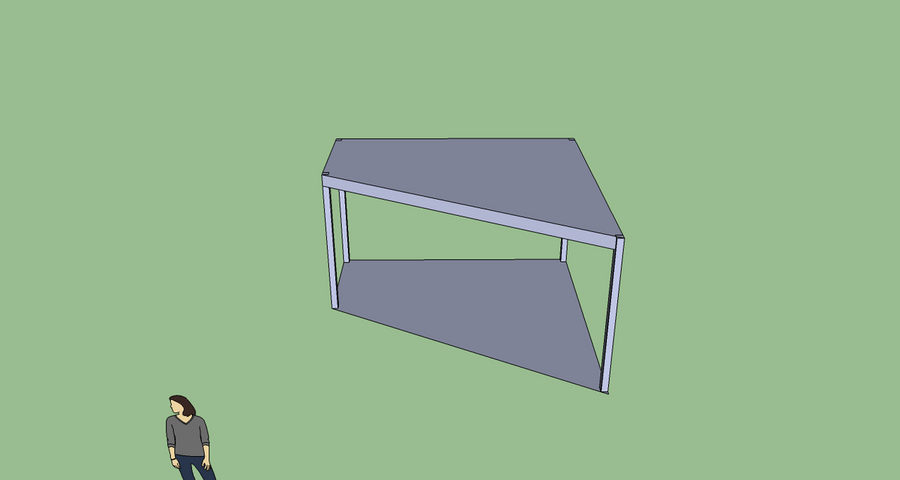

Here is a rough drawing. I'm thinking 2x8's around the edges, 2x6's 2' apart and 3/4" OSB for the upstairs floor, 4x4's for the uprights, and 2x4's and 3/4" OSB for the bottom floor. Also, I'm thinking roughly 6-8" casters with brakes - 7 for each platform - 1 in each corner, and 1 in the middle of each side except the short side which is only 6'. Let me know what you think.

Here is a rough drawing. I'm thinking 2x8's around the edges, 2x6's 2' apart and 3/4" OSB for the upstairs floor, 4x4's for the uprights, and 2x4's and 3/4" OSB for the bottom floor. Also, I'm thinking roughly 6-8" casters with brakes - 7 for each platform - 1 in each corner, and 1 in the middle of each side except the short side which is only 6'. Let me know what you think.