I’m designing a production taking place in a church basement gymnasium. This will be the first theatrical production to happen in the space.

There is ample power available, although the existing switches are in an electrical room which is not near the performance area. The existing installation contains (1) spare (unused) 100-Amp 3-phase breaker plus (2) spare 60-Amp 3-phase breakers. We hope to use one 60-Amp for audio, and the rest of the power for lighting.

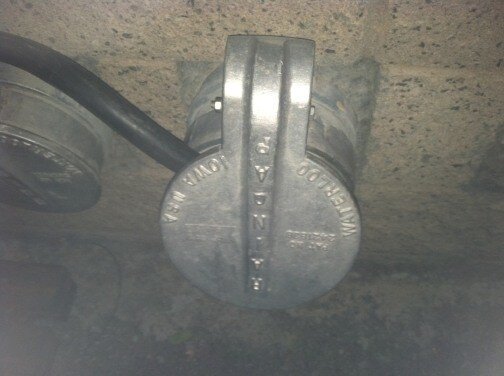

Between the electrical room and the gymnasium is a storage room. This room (masonry construction) has sprinklers. This would seem an ideal location for portable dimmer packs. The church is amenable to doing the appropriate electrical work (licensed electrician) to install a few company switches (i.e., Lex Products with Cam-Lok outputs) in this storage room which would extend the available power from the electrical room.

My questions:

1. I need to specify a completely legal way for portable multicables to pass from the dimmer racks in the storage room to the performance area through a masonry wall. This would be akin to sending cables through a “mouse hole” in the proscenium of a theatre, I presume. I’ve seen fire-rated metal access doors (12” square) which would preserve the integrity of the masonry wall when the door was closed. When the door is open to pass the portable cables, I understand I might use fire-stop pillows to pack the space around the cables in the opening.

In a thread called “NEC Code Applicability,” Steve Terry wrote:

Portable cables can penetrate walls, floors, or ceilings through approved "pass-through" chases. (a mouse-hole that was not fire-stopped would no doubt be a stretch).

What exactly is an “approved pass-through chase?”

I need to know if this idea is viable and legal, and if so if there is a recommended manufacturer and model for the pass-through chase hardware. By the way, this is in New York City.

2. What height would be appropriate for the pass-through chases? Floor level seems a trip hazard. The cables will mostly be running up the wall (i.e., along a boom or taildown) to rigged pipes at +16’-0”; the storage room ceiling at 7’-0” limits locating the chase at grid level.

3. Are there rules or restrictions governing the height and/or location of installed company switches?

4. Are there other factors I need to consider?

Any advice is most appreciated.

There is ample power available, although the existing switches are in an electrical room which is not near the performance area. The existing installation contains (1) spare (unused) 100-Amp 3-phase breaker plus (2) spare 60-Amp 3-phase breakers. We hope to use one 60-Amp for audio, and the rest of the power for lighting.

Between the electrical room and the gymnasium is a storage room. This room (masonry construction) has sprinklers. This would seem an ideal location for portable dimmer packs. The church is amenable to doing the appropriate electrical work (licensed electrician) to install a few company switches (i.e., Lex Products with Cam-Lok outputs) in this storage room which would extend the available power from the electrical room.

My questions:

1. I need to specify a completely legal way for portable multicables to pass from the dimmer racks in the storage room to the performance area through a masonry wall. This would be akin to sending cables through a “mouse hole” in the proscenium of a theatre, I presume. I’ve seen fire-rated metal access doors (12” square) which would preserve the integrity of the masonry wall when the door was closed. When the door is open to pass the portable cables, I understand I might use fire-stop pillows to pack the space around the cables in the opening.

In a thread called “NEC Code Applicability,” Steve Terry wrote:

Portable cables can penetrate walls, floors, or ceilings through approved "pass-through" chases. (a mouse-hole that was not fire-stopped would no doubt be a stretch).

What exactly is an “approved pass-through chase?”

I need to know if this idea is viable and legal, and if so if there is a recommended manufacturer and model for the pass-through chase hardware. By the way, this is in New York City.

2. What height would be appropriate for the pass-through chases? Floor level seems a trip hazard. The cables will mostly be running up the wall (i.e., along a boom or taildown) to rigged pipes at +16’-0”; the storage room ceiling at 7’-0” limits locating the chase at grid level.

3. Are there rules or restrictions governing the height and/or location of installed company switches?

4. Are there other factors I need to consider?

Any advice is most appreciated.