hobbsies

Active Member

This is a rant post, I'm sorry I have to complain. I'm so frustrated with all brands of them, Altman and especially LE, I'm looking at you.

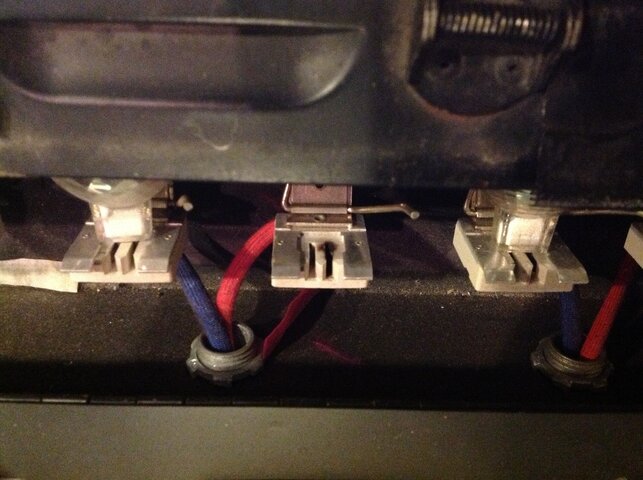

How the F am I supposed to change these sockets (see pics)? Good thing they weren't dead hung, they were on the ground row.. I don't normally carry a riveter with me, but even if I did, I would have to remove the entire backside and underside of the unit to get at the wires and the back side of the rivets. These sockets are things that have to be swapped often. I don't understand why they were designed this way in this particular unit. Wtf?

How the F am I supposed to change these sockets (see pics)? Good thing they weren't dead hung, they were on the ground row.. I don't normally carry a riveter with me, but even if I did, I would have to remove the entire backside and underside of the unit to get at the wires and the back side of the rivets. These sockets are things that have to be swapped often. I don't understand why they were designed this way in this particular unit. Wtf?