You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Name that (Big!) Connector: G4100/stage plug

- Thread starterFooter

- Start date

Does it make you old when I knew what the odd thing in the corner was without thinking? I'll stay out of the connector question for now.

I would have to say no also... I had 2 college prof's that insisted we all learn 'ancient' theatre methods in tech classes. And that along with flat lashing was on the list...!

Does it make you old when I knew what the odd thing in the corner was without thinking? I'll stay out of the connector question for now.

No, it doesn't make me old because you know what that odd thing in the corner is at all...

Posted at Footer's request...

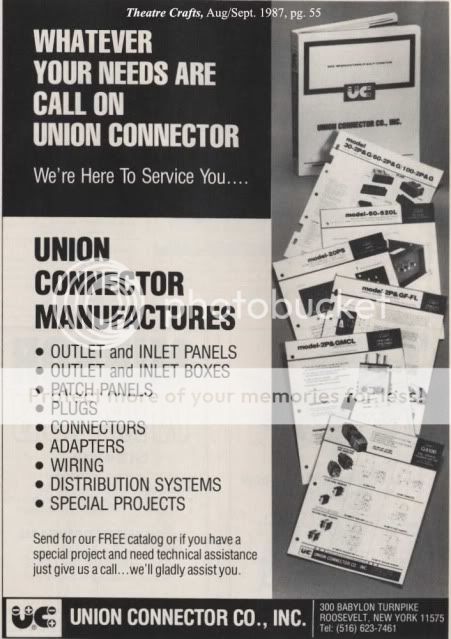

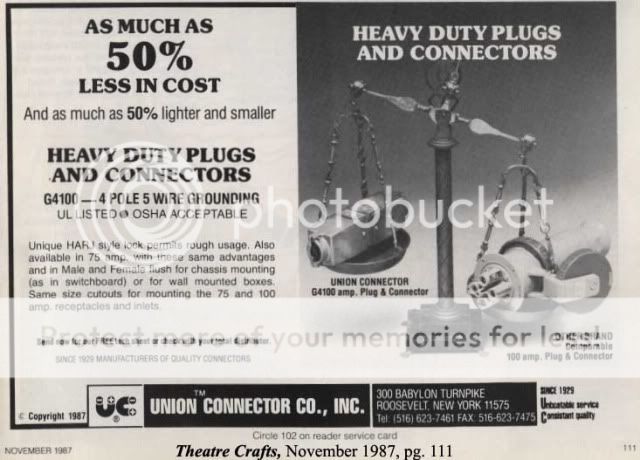

While I don't have a manufacturer's cut sheet (left behind in a cross-country move), I was able to find and scan two print ads.

(Cut sheet on top of the pile in the photo.)

These were used to power the portable dimmer packs (CD80 and D192) at the Royal-George and Briar Street theatres in Chicago, and likely still are.

Perhaps someone can tell us when and why the connector became extinct?

While I don't have a manufacturer's cut sheet (left behind in a cross-country move), I was able to find and scan two print ads.

(Cut sheet on top of the pile in the photo.)

These were used to power the portable dimmer packs (CD80 and D192) at the Royal-George and Briar Street theatres in Chicago, and likely still are.

Perhaps someone can tell us when and why the connector became extinct?

STEVETERRY

Well-Known Member

Would it have something to do with the materials used in the connector?

Sent from my iPhone using Tapatalk

Actually, no. The materials were fairly conventional phenolic, cast aluminum, and brass.

This connector was introduced during a time when it was not clear that the NEC would allow single-pole separable connectors without sequential interlock. Pin-and-sleeve 5-pole 100A connectors available were huge and expensive, for good reason.

The G4100 was an attempt to shrink the size and cost of a 5P 100A connector. It failed miserably because:

A. You could barely get the requisite 100A conductors terminated.

B. It was almost impossible to mate due to the ridiculously high insertion force of 5 split pins.

Then came the icing on the cake: a series of violent connector explosions where insulation failed in the phenolic block or the silly fiber shroud that protected the metal backshell from coming into contact with the pins or conductors. One of the weaknesses of the pin retention into the block was that it used metal roll pins. The holes drilled in the block for these, and the lack of precision in setting the pins proved to be a problem. As I recall, there were some injuries.

That was it: connector discontinued.

But think about it: a 5-pole 100A connector for use in the theatre? I think not! When you do the calculations on the ampacity of a 5-conductor SO cord with 4 current-carrying conductors, you end up with a piece of cable that a)was not made and b)would never fit in the connector, and c) was a guaranteed hernia.

Therefore, the industry quickly concluded that at the three-phase 100A level, single-conductor cables and connectors were a requirement.

ST

Last edited:

Hmm, fascinating on the plug. Never seen one before. Interesting they would think this was good for 100A given the pin size and that a neutral back than would be larger, I thought oversized or double neutrals were more a modern concept.

Funny also it wasn't big enough to fit the cable it was meant to fit, I might think it 30A in comparison to the Gam Check, perhaps 60A if pushing it which might have fit the multi-cable. Perhaps was desgned for one thing and used for another? What's stamped on the plug for amperage rating?

Stage brace, got one from 1926 and I still frequently use it. Also have boxes full of parts to them and the old style stage screw, the newer style with the insert and various other parts. Granted these days I don't use it for supporting scenery - though I did grow up with that practice which was the norm for soft and even some hard flats on flat I was using. A weighted brace jack would only support X amount of scenery in height, after that you really did need a stage brace. Even at one point learned to use them in screwing to say a 12"x18" double plywood block that had a rubber bottom. Load the block up with stage weights as you would with a brace jck so as not to destroy the floor and it was still a viable option when I was doing scenery. Haven't lash lined scenery since the mid-80's but grew up with that also. Still viable for quick box set scenery changes asuming enough manpower or castered tip jacks for the scenery. Granted with these weighted brace techniques you kind of needed either a lot of people to carry the weights off stage or a few carts ready to ge loaded. I tended to use such brace jacks instead of foot irons also - such plates were another purpose of the stage screw.

Quick and quiet scene changes. Other ways to do it these days - most of them are more expensive or would take longer and be more noisy. (I'll post that question in the scenery section.)

Over the years at least for me, pulling gel without having to fly in the lighting was a really good use for a stage brace. The old theater I worked at had entire racks of them so I could pick my brace for the distance I needed it to travel. I only have one now - traded some scrap steel for it the theater needed. These days I use it for pulling tape off my 14' high tape wall (rolls of tape on 18" pipe lengths mounted to a board and filled with every type of tape available.) A bannister with perpendicular mounted and ground down bracket for it works a little better for this purpose but the stage brace is still useful in the shop.

Mainly today I use it to either lift up cable sag for my deprtment's wire rope hoist we use to hang prototype lights with - hook the extra cable once the light is hoisted up and cable tie the stage brace to a shelf near by. Works perfect for this. Other purpose is to as with the above grab stuff say on a flown truss without having to fly back in the truss - or adjust fixtures. It's around 20' extension length with hooks comes in really handy.

Funny also it wasn't big enough to fit the cable it was meant to fit, I might think it 30A in comparison to the Gam Check, perhaps 60A if pushing it which might have fit the multi-cable. Perhaps was desgned for one thing and used for another? What's stamped on the plug for amperage rating?

Stage brace, got one from 1926 and I still frequently use it. Also have boxes full of parts to them and the old style stage screw, the newer style with the insert and various other parts. Granted these days I don't use it for supporting scenery - though I did grow up with that practice which was the norm for soft and even some hard flats on flat I was using. A weighted brace jack would only support X amount of scenery in height, after that you really did need a stage brace. Even at one point learned to use them in screwing to say a 12"x18" double plywood block that had a rubber bottom. Load the block up with stage weights as you would with a brace jck so as not to destroy the floor and it was still a viable option when I was doing scenery. Haven't lash lined scenery since the mid-80's but grew up with that also. Still viable for quick box set scenery changes asuming enough manpower or castered tip jacks for the scenery. Granted with these weighted brace techniques you kind of needed either a lot of people to carry the weights off stage or a few carts ready to ge loaded. I tended to use such brace jacks instead of foot irons also - such plates were another purpose of the stage screw.

Quick and quiet scene changes. Other ways to do it these days - most of them are more expensive or would take longer and be more noisy. (I'll post that question in the scenery section.)

Over the years at least for me, pulling gel without having to fly in the lighting was a really good use for a stage brace. The old theater I worked at had entire racks of them so I could pick my brace for the distance I needed it to travel. I only have one now - traded some scrap steel for it the theater needed. These days I use it for pulling tape off my 14' high tape wall (rolls of tape on 18" pipe lengths mounted to a board and filled with every type of tape available.) A bannister with perpendicular mounted and ground down bracket for it works a little better for this purpose but the stage brace is still useful in the shop.

Mainly today I use it to either lift up cable sag for my deprtment's wire rope hoist we use to hang prototype lights with - hook the extra cable once the light is hoisted up and cable tie the stage brace to a shelf near by. Works perfect for this. Other purpose is to as with the above grab stuff say on a flown truss without having to fly back in the truss - or adjust fixtures. It's around 20' extension length with hooks comes in really handy.

Aye, 'twas a valued man he that could remove, and insert, a gelframe using a stage brace.... Over the years at least for me, pulling gel without having to fly in the lighting was a really good use for a stage brace. ...

Scrollers? We doan need no steenkin scrollers!

Nice! Fascinating. What size cable was feeding these 100A plugs? I know I have some 4/5 SO cable about and it's huge. So it's center ground, that is also interesting but sensible. Is that center ground pin point of first contact also? Can I play in your shop for the day? Seems like fun work this cleaning.

Especially love the Scooby Doo mystery hunt quick results.

Especially love the Scooby Doo mystery hunt quick results.

Last edited:

Something only 23 years old not modern? P'shaw!... that this is not at all a modern connector. ...

Something only 23 years old not modern? P'shaw!

As modern as this (which I have one of these stuffed in a storage unit)...

Compaq III Portable computer

Or this... (if it did not catch on fire that is)

STEVETERRY

Well-Known Member

They probably used a similar tool to install the cable. I assembled a few of these, and it was not fun!

Note the .125" holes in the phenolic block. These were the scene of the crime in the flash/bang connector explosions.

Also note the ridiculous fiber shroud to insulate the metal backshell.

These pix remind me that this is one of the worst connectors ever conceived.

ST

ST

Last edited by a moderator:

Bold statement, seeing as how this connector... These pix remind me that this is one of the worst connectors ever conceived. ...

was sold and used for at least 70 years. I know, I know, two wrongs don't make a right, but three lefts do!

Was the UL-Listing on the G4100 ever rescinded, or do we just not talk about that?

Was the UL-Listing on the G4100 ever rescinded, or do we just not talk about that?

Not from the looks of things...

RUFR.E11417 - Receptacles, Stage Type

Bold statement, seeing as how this connector

was sold and used for at least 70 years. I know, I know, two wrongs don't make a right, but three lefts do!

Was the UL-Listing on the G4100 ever rescinded, or do we just not talk about that?

That looks vaguely familiar... Was that the connector that Doc Brown used in Back to the Future when he hooked up the cable to the lightning rod above city hall?

STEVETERRY

Well-Known Member

Bold statement, seeing as how this connector

was sold and used for at least 70 years. I know, I know, two wrongs don't make a right, but three lefts do!

Was the UL-Listing on the G4100 ever rescinded, or do we just not talk about that?

And that was a reliable connector, too! No internal arcing or termination difficulties here! Any problems, you could see them!

ST

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 48

- Views

- 13K

- Replies

- 0

- Views

- 2K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)