You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

resistor colour codes

- Thread starterHughesie

- Start date

Um... I think you may be refering / confusing two different things.

Resistors are labled according to a standard color coding scheme. This is demonstrated here: http://www.dannyg.com/examples/res2/resistor.htm

Seperately, some people lable cable lengths with their own color codeing systems distinguishing different lenghts of cable, having nothing to do with resistance.

I hope this helps abit!

Resistors are labled according to a standard color coding scheme. This is demonstrated here: http://www.dannyg.com/examples/res2/resistor.htm

Seperately, some people lable cable lengths with their own color codeing systems distinguishing different lenghts of cable, having nothing to do with resistance.

I hope this helps abit!

So your saying you put a band of colour every 5' so you just add up the bands of colour to tell how long a cable is?

This sounds horribley enefficent, Try some heat shrink with printed length lablels. and use a colour code to determine the type of cable. or use a printed length with a single colour band to determine length such as red for 8' green for 16' blue for 32' white for 56' etc......

JH

This sounds horribley enefficent, Try some heat shrink with printed length lablels. and use a colour code to determine the type of cable. or use a printed length with a single colour band to determine length such as red for 8' green for 16' blue for 32' white for 56' etc......

JH

jonhirsh said:So your saying you put a band of colour every 5' so you just add up the bands of colour to tell how long a cable is?

This sounds horribley enefficent, Try some heat shrink with printed length lablels. and use a colour code to determine the type of cable. or use a printed length with a single colour band to determine length such as red for 8' green for 16' blue for 32' white for 56' etc......

JH

Nearly every house i have worked in runs that system or something simular. Usually I prefer to hard label any cable over 50' so i dont have more then 5 bands on it, but in the lighting world you rarely have tons of cable over 50' that is not a multi. Also, in the space i am currently working in we have cable ranging from 5' to 50' with nearly every 5' increment in between. Doing a color code of these would be nearly impossible to remember let alone tell hands that show up the day of how the system works. Simply saying if you see 3 red bands its a 30', if you see 3 red bands and a green one its a 35'.

Also, you put the bands at each connector, not every 5' or so.

but if you put numbers that say 5' on the connector end its sooooo much simpler no counting you can tell at a glance.

As to the 50' long cables not being prevelent in the lighting world, i feel that that opinion might be specific to your area but everywhere i work we almost never use multi unless its a tour. The TV show im on now has no twist or edison shorter then 56' and they top out at about 96' (christie lites does 8' increments btw.) so when your talking about supper long cables having a simple way to tell length is key.

JH

As to the 50' long cables not being prevelent in the lighting world, i feel that that opinion might be specific to your area but everywhere i work we almost never use multi unless its a tour. The TV show im on now has no twist or edison shorter then 56' and they top out at about 96' (christie lites does 8' increments btw.) so when your talking about supper long cables having a simple way to tell length is key.

JH

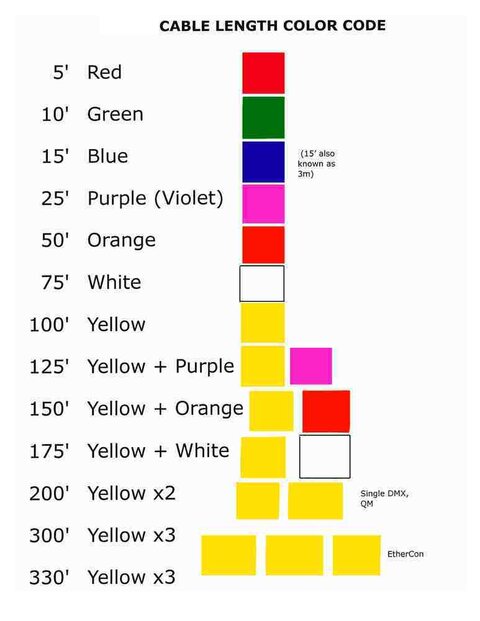

Well, if you're going to use resistor code, use it for ORDER, not NUMBER. IE, Brown=5', Red=10', Orange="25', Yellow=50', Green=100', etc. Typically you don't code lengths other than this, instead using combinations. So a 75' would be orange and yellow, a 300' would have three green stripes, etc.

Although we use a different color scheme, this is the basic concept we use in our shop, and in most other shops I've worked at/with.

Why not just write a number? Because now from across the stage I can spot a 50' cable and point it out to somebody, or know which pile I need to head to. After a little while working with a particular code, it'll become second nature.

FWIW, the color code that our shop uses, as well as at least one lighting shop that I know, is:

10'=green

15'=blue

25'=purple

50'=orange

100'=yellow

There is a code for 75', but it's fallen out of use in place of purple+orange, so I couldn't even tell ya what it is off the top of my head.

--A

Although we use a different color scheme, this is the basic concept we use in our shop, and in most other shops I've worked at/with.

Why not just write a number? Because now from across the stage I can spot a 50' cable and point it out to somebody, or know which pile I need to head to. After a little while working with a particular code, it'll become second nature.

FWIW, the color code that our shop uses, as well as at least one lighting shop that I know, is:

10'=green

15'=blue

25'=purple

50'=orange

100'=yellow

There is a code for 75', but it's fallen out of use in place of purple+orange, so I couldn't even tell ya what it is off the top of my head.

--A

So for the heat shrink method that's easy enough to get ahold of, however what do you recommend for making the number text on? Obviously paper would tear easily under the shrink, is there a nylon preprinted number that you can stick onto it and heat shrink over it?

Also for tying cables what do you guys recommend, you can use the ol rope trick and use the knot that goes around it then you can bow tie it. However I've seen on pre-made cables they have a heavy looking heatsrhink with the rope coming out of it so the rope never comes loose. Do they have these pre made?

Also for tying cables what do you guys recommend, you can use the ol rope trick and use the knot that goes around it then you can bow tie it. However I've seen on pre-made cables they have a heavy looking heatsrhink with the rope coming out of it so the rope never comes loose. Do they have these pre made?

Do a Google search for "cable labels" or "cable markers", there are numerous options including preprinted or custom labels you create, various methods of attachment and things like self covering labels with a clear portion that wraps over the printed portion of the label. Brady is probably the biggest name in this market but there are many others.

I personally like velcro cable ties like these, Rip-Tie Index.

I personally like velcro cable ties like these, Rip-Tie Index.

I use the colored rings from Neutrik. I put them on the Male end of the cable so they aren't visible to the audience. Resistor code is too complicated for most people so I just keep them in rainbow order:

Red: 15ft

Orange: 25ft

Yellow: 40ft

Green: 50ft

Blue 75ft

Purple 100ft

Black, white, and gray are all patch (XLR or 1/4") cables:

White: 1.5ft

Gray: 3ft

Black 6ft

I'm not a fan of velcro ties. They get caught on one-another in the bin and can become a mess. I use 18" strands of tie-line, knotted on both ends and tied about 12-18" from the male end of the cable. A loose square-knot holds to cable from unraveling. Hope this helps.

Red: 15ft

Orange: 25ft

Yellow: 40ft

Green: 50ft

Blue 75ft

Purple 100ft

Black, white, and gray are all patch (XLR or 1/4") cables:

White: 1.5ft

Gray: 3ft

Black 6ft

I'm not a fan of velcro ties. They get caught on one-another in the bin and can become a mess. I use 18" strands of tie-line, knotted on both ends and tied about 12-18" from the male end of the cable. A loose square-knot holds to cable from unraveling. Hope this helps.

Similar threads

- Replies

- 1

- Views

- 506

- Replies

- 9

- Views

- 523

- Replies

- 2

- Views

- 320

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)