I wasn't going to respond, then Dave posted a link on the

SML and I figured I would...I am not a rigger, but I am an engineering student and figured I would try it out

There are five unknowns, therefore we need five distinct equations. We can assume symmetry, that gives us RA=RE and RB=RD. We have the sum of the forces acting vertically must be zero, or 600=2RA+2RB+RC. We have the three moments equation applied to points ABC and applied to

BCD.

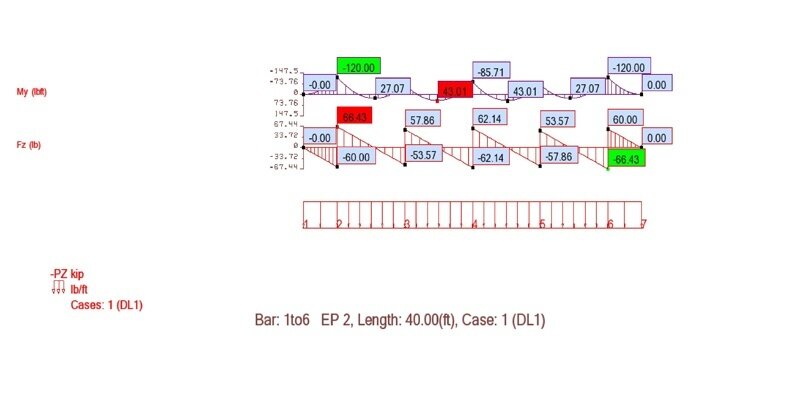

For the three moments theorem, we need to do some fancy math. I worked out the shear and moment diagrams on paper. Bending moments are:

MA=0, MB=10RA-750, MC=20RA+10RB-3000, MD=30RA+20RB+10RC-6750, ME=40RA+30RB+20RC+10RD-12000.you simplify that equation

We can check this result by finding that the bending moment at each end is zero. ME=0, and if you simplify that equation it is the same as the first equation for forces.

For the first three moments calculation:

0*10+2*(10RA-750)*20+(20RA+10RB-3000)*10=1/4*15*10^3+1/4*15*10^3

And for the second:

(10RA-750)*10+2*(20RA+10RB-3000)*20+(30RA+20RB+10RC-6750)*10=1/4*15*10^3+1/4*15*10^3

Solving these yields, according to my calculator, RA=91.1, RB=128.6, RC=160.7

Upon realizing that I am the only one with this answer I ran the calculations again. Here are all the equations:

(

VAR is the shear force (V) just slightly to the right side (R) or

point (A), the bending moments are calculated by (Area of the triangle)-(Width)*(Displacement below 0))

RA unknown

RB unknown

RC unknown

RD=RB

RE=RA

VAR=RA

VBL=VAR-150

VBR=VBL+RB

VCL=VBR-150

VCR=VBR+RC

VDL=VCR-150

VDR=VDL+RD

VEL=VDR-150

MA=0

MB=MA+10*(VAR-VBL)/2+10*VBL

MC=MB+10*(VBR-VCL)/2+10*VCL

MD=MC+10*(VCR-VDL)/2+10*VDL

ME=MD+10*(VDR-VEL)/2+10*VEL

RA+RB+RC+RD+RE=600

MA*10+2*MB*20+MC*10=1/4*15*10^3+1/4*15*10^3

MB*10+2*MC*20+MD*10=1/4*15*10^3+1/4*15*10^3