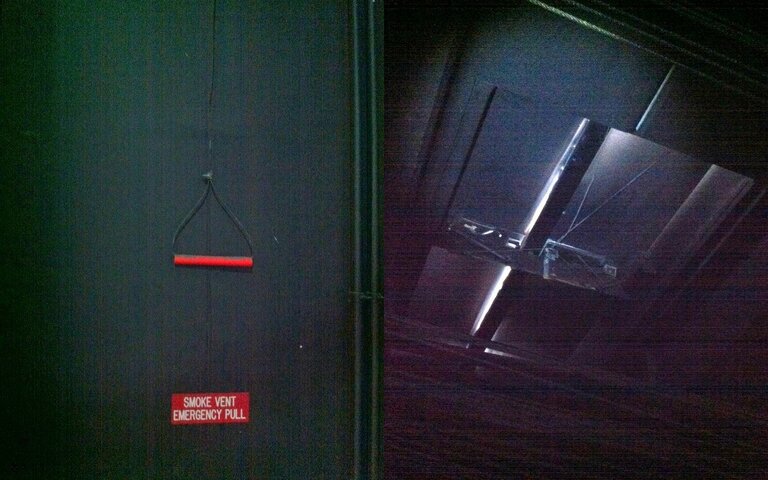

Some better designed systems have a method to

winch them closed. Ours do not.

With ours, it's more like 4 people standing on top of ea. door, 8 doors total. They need to be closed as a pair, so 6-8 people required.

This is mostly due to the strength of the pistons that pop the doors. Our doors as well, have a surface metal that resembles the "Spirit of St. Louis" Lindbergh plane, so a highly polished metal. Treacherous to stand on in the rain/snow.

You can reset the doors only after resetting the

power to the mechanism to re-set the magnetic

release latch. We discovered this after much trial and error.

Our

system opened one night mid-show, when the

smoke detector sensed too much theatrical

smoke. It was raining, then snowing and we literally had to wait till after the dance company

load out before climbing to the roof. Then 8 people climb on top, hoping to not slip and fall the 20 feet

thru the roof and onto the

gridiron.

After this incident we removed the

smoke detector, code be damned.

They subsequently installed a powered roof venting

system, on a generator, that is supposed to render the roof doors obsolete, which is a good thing due to what had been three total systems in our facility, that have triggered a total of 6 times over the past 10 years or so. We now

call our Public

Safety and Facilities Departments and refuse to deal with them.