So here's the problem.

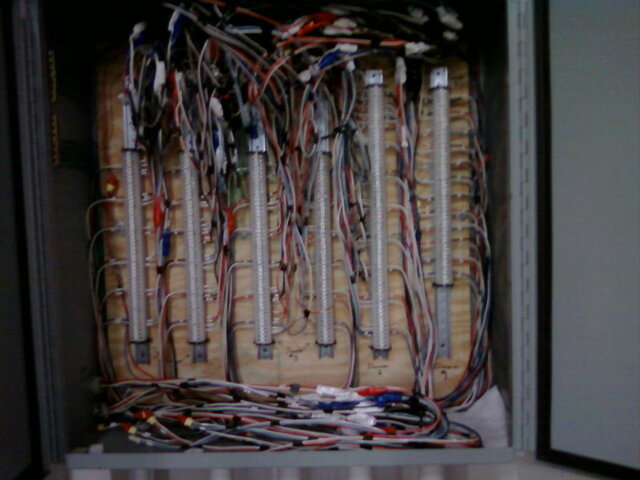

I was working with a Church, they recently moved into a new building. I was not around for the install of any of the electrics, dimming, or Patch bay (A nightmare in and of itself.) Anyway I had finished the show and was turning it around for their regular services and ran into a few snags. When I plugged lights into certain channels they would not work. They were plugged in correctly, Plug is wired correctly, Lamp is good, patched correctly (both in the physical patch bay and in the light board) fuses on the dimmer were good, and there was power coming from the dimmer to that channel in the patch bay. I know I metered it, going up to the cat walks at the actual pug, nothing. by all accounts the outlet should have power, but it doesn't

When I plugged lights into certain channels they would not work. They were plugged in correctly, Plug is wired correctly, Lamp is good, patched correctly (both in the physical patch bay and in the light board) fuses on the dimmer were good, and there was power coming from the dimmer to that channel in the patch bay. I know I metered it, going up to the cat walks at the actual pug, nothing. by all accounts the outlet should have power, but it doesn't  I am not able to physicaly trace these lines at all.

I am not able to physicaly trace these lines at all.

We had an event happen during the show that is relevent. We had an individual dimmer blow as in sparks fly the whole nine yards. There has to be a short somewhere in the line, or the dimmer. There was nothing plugged in and it would still throw sparks. These channels are in the same pack as the one that blew.

What am I missing?

I was working with a Church, they recently moved into a new building. I was not around for the install of any of the electrics, dimming, or Patch bay (A nightmare in and of itself.) Anyway I had finished the show and was turning it around for their regular services and ran into a few snags.

We had an event happen during the show that is relevent. We had an individual dimmer blow as in sparks fly the whole nine yards. There has to be a short somewhere in the line, or the dimmer. There was nothing plugged in and it would still throw sparks. These channels are in the same pack as the one that blew.

What am I missing?