We have to replace a stage in our room. Currently we are using 4x8 temp staging bolted together into a stage 24 wide and between 8 and 16 feet deep. The stage has become squeaky and noisy, plus with acoustic drums and electric bass on it, it is really a boomy drumhead.

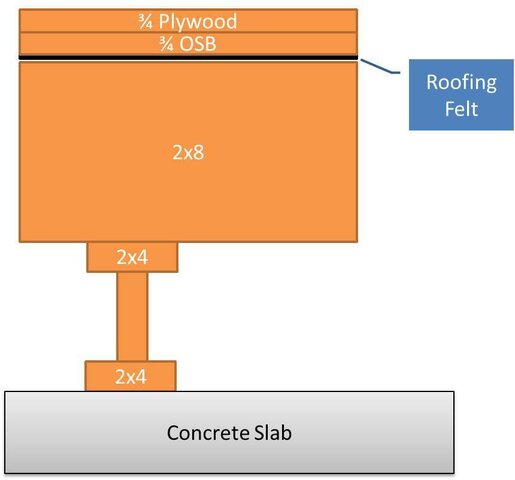

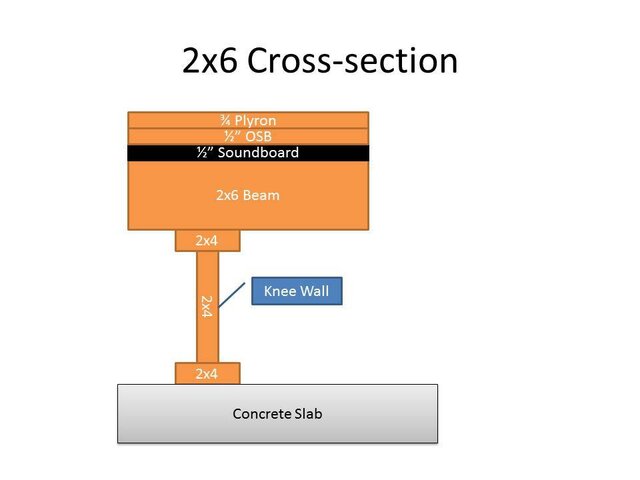

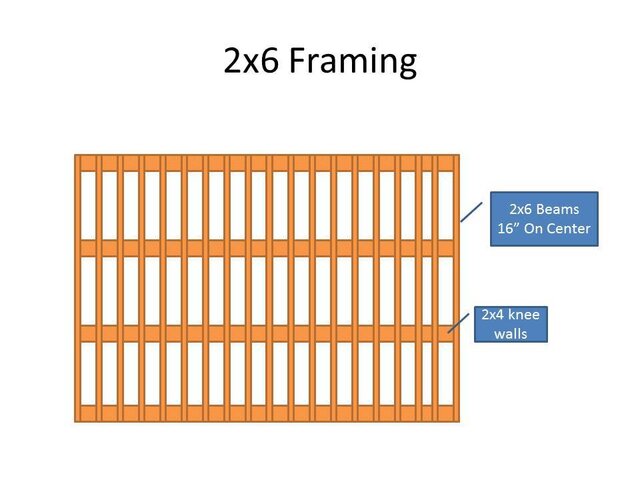

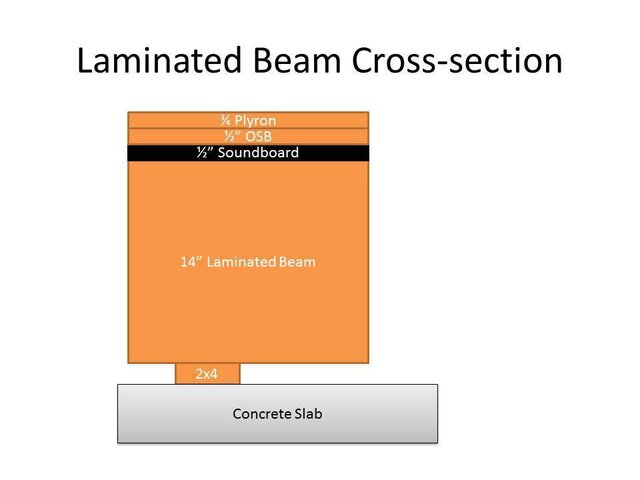

We are going to replace this stage with a new one. Here are the details. The room is 50'x50' with 16' high ceilings. The new stage will be 24' wide X 18' deep (rectangle), and a height of 16 inches. It will be permanently installed. The top will be either painted black or dark carpet. I will have one stage box at middle downstage with two power outlets, 2 XLR returns for monitors, and 3-4 XLR sends for mics. All other connectivity will be on the wall backstage. Stage is used for speaking and music - live acoustic drums, electric guitars and bass, keyboards, etc.

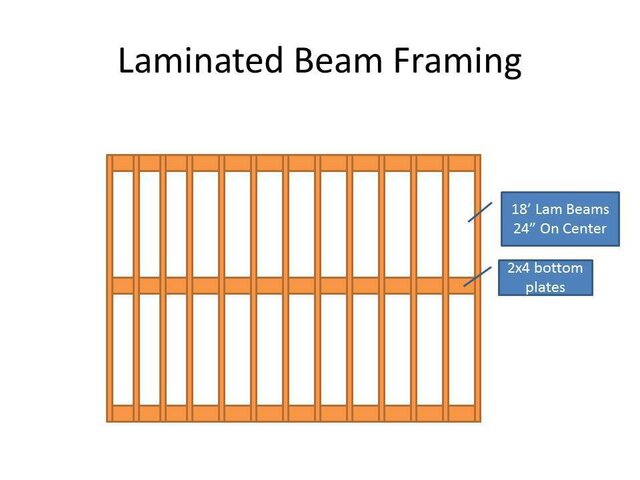

I have spent a couple of hours searching and browsing the forums looking for details on stage construction technique and most of what I found was geared towards platforms and temporary staging. While the flooring info was thorough, I'm still stuck trying to understand the best way of framing the stage. I also am looking for suggestions on how best to remove resonance to decrease mic rumble.

We are going to replace this stage with a new one. Here are the details. The room is 50'x50' with 16' high ceilings. The new stage will be 24' wide X 18' deep (rectangle), and a height of 16 inches. It will be permanently installed. The top will be either painted black or dark carpet. I will have one stage box at middle downstage with two power outlets, 2 XLR returns for monitors, and 3-4 XLR sends for mics. All other connectivity will be on the wall backstage. Stage is used for speaking and music - live acoustic drums, electric guitars and bass, keyboards, etc.

I have spent a couple of hours searching and browsing the forums looking for details on stage construction technique and most of what I found was geared towards platforms and temporary staging. While the flooring info was thorough, I'm still stuck trying to understand the best way of framing the stage. I also am looking for suggestions on how best to remove resonance to decrease mic rumble.