iLightTheStage

Active Member

So, I want to pick all of your brains because I can't think of a way to do this but I feel like it's possible:

How could I build a tool to test which wattage (375w/575w/750w) lamp is inside a source4 without removing the cap?

I'd like to go with the simplest solution, and avoiding advanced electronics such as ICs and such. We currently open caps on large pulls to make sure the lamps are set correctly for the gig (some of our guys are lazy and don't label the fixture when they change the lamp from the 575w we default to). But it would be much nicer to be able to plug in the fixture to determine that the lamp is good AND the right wattage. [sidenote: I much prefer testing the lamp by plugging it in, because continuity will never tell you that the lamp was about to blow.]

How could I build a tool to test which wattage (375w/575w/750w) lamp is inside a source4 without removing the cap?

I'd like to go with the simplest solution, and avoiding advanced electronics such as ICs and such. We currently open caps on large pulls to make sure the lamps are set correctly for the gig (some of our guys are lazy and don't label the fixture when they change the lamp from the 575w we default to). But it would be much nicer to be able to plug in the fixture to determine that the lamp is good AND the right wattage. [sidenote: I much prefer testing the lamp by plugging it in, because continuity will never tell you that the lamp was about to blow.]

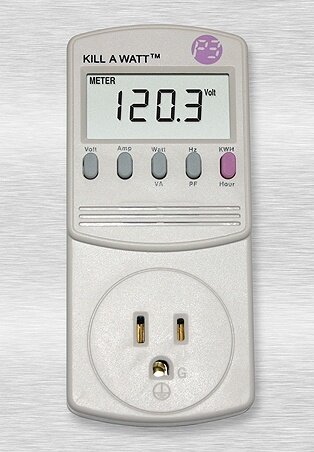

Here's your answer; forgot about this:

Here's your answer; forgot about this: