The fact that you've noticed they're wired incorrectly is enough. If they haven't wired the cables correctly, who knows what other problems might exist?

The proper thing to do is to take them out of circulation, tag them, and then have an afternoon or day of repairing them. Are the "new guys" students?

Overhire? See if you can get them involved to properly train them.

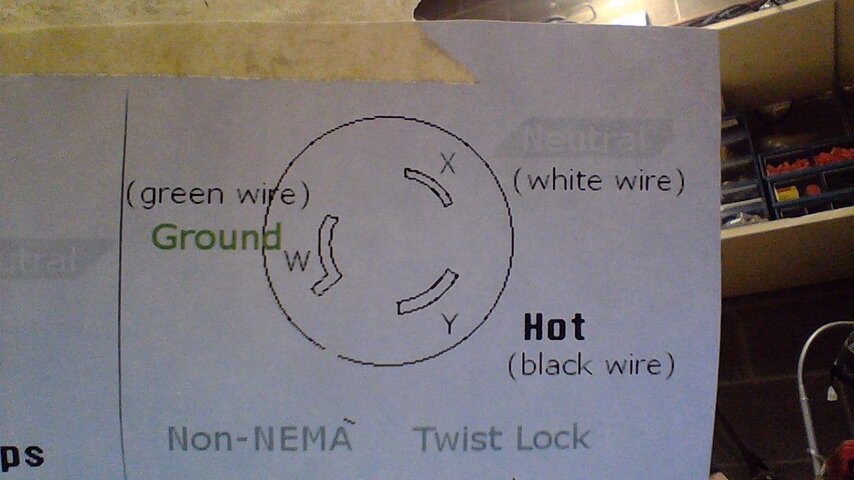

Reversing the hot and the

neutral (the black and white wires) causes a number of problems, typically with switches and dimmers. One potential problem would be switching off the

neutral rather than the hot, which would result in having 240vac rather than a dead

circuit.

You can't magically make 240v from a 120v

circuit. Switching a "

Neutral" (in this case actually not

neutral, actually '

identified') does not create 240v, but does leave 120v still potentially present at the device, all the way to the

switch. This is not safe at all.

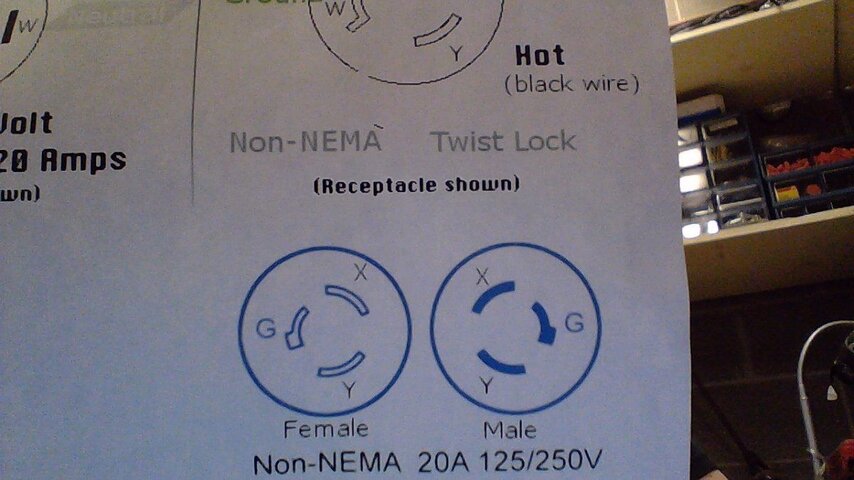

Those Non-NEMA connectors shown in the

image "non

nema 2" are indeed a 240v

connector that is why they are labeled that way. They not not intended for 120v, none the less they have been used for 120v as previously mentioned. As long as its all the same it will work fine. Any 120v

twist lock will have three different pin shape/sizes (like non

nema image), you'll notice that two of the pins on that

connector look the same, that is because they are both intended to be 'hot' for 240v.

I'd say its best if at some time to make sure 120v designed connectors are used on 120v, 240 on 240. This way noone may be "stupid" at connect something of the wrong

voltage.

About cables being wired backwards. Generally if they wired them backwards, they obviously don't know what they are doing and the cables should be all checked. Generally if they wired them backwards you'll also see things like WAY too much of the

jacket stripped off (thus lots of

wire stuffed into the

connector), strain reliefs incorrectly installed,

insulation inside the connection, too much of the

wire stripped and about to short out,

etc,

etc. You can't just toss people a cable,

plug end, and tools and say "have at it". Making cables is much more invovled than some may think. Most people have never made a cable in their lives. HOW MANY CABLES EVEN IN PRO OR SEMI PRO THEATRES HAVE I SEEN MADE WRONG?! The answer is too many for my own comfort. The second I see a suspect cable in the field I look at it, and if it fails my inspection even in some small way I cut the ends off or repair it.