You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

C-Clamps vs O-Clamps

- Thread starterepicket1

- Start date

JLNorthGA

Active Member

I like C-clamps for a number of reasons. They are easy to put on, you can rotate the post by loosening a nut and they are relatively inexpensive. They can work well with a number of different diameter pipes.

The negative about a C-clamp is that you have to make sure it is seated correctly on the bar before tightening.

O-clamps are pretty much sized to a particular pipe diameter. Rotating the lighting fixture is not quite as easy (or secure IMO). They are very secure when sized correctly.

YMMV - I started with C-clamps many years ago and haven't really found a reason to change.

The negative about a C-clamp is that you have to make sure it is seated correctly on the bar before tightening.

O-clamps are pretty much sized to a particular pipe diameter. Rotating the lighting fixture is not quite as easy (or secure IMO). They are very secure when sized correctly.

YMMV - I started with C-clamps many years ago and haven't really found a reason to change.

What will you be hanging these Fresnels from? 1.5" ID iron pipe? Truss? Aluminum tube?... I have C-clamps that came with some Times Square Lighting fresnels, but thinking about buying O-Clamps. Thank you.

Most, if not all, O-Clamps are primarily made from plastic, which may be acceptable when hanging lighting DJ-type fixtures but I don't want them over my head.

All are a slightly more refined version of a half-coupler.

Stick with the c-clamp and get yourself some truss protector s or Perma Penny s. I'm sure your lighting budget has better things to be spent upon than replacing perfectly serviceable clamps.

.

JD

Well-Known Member

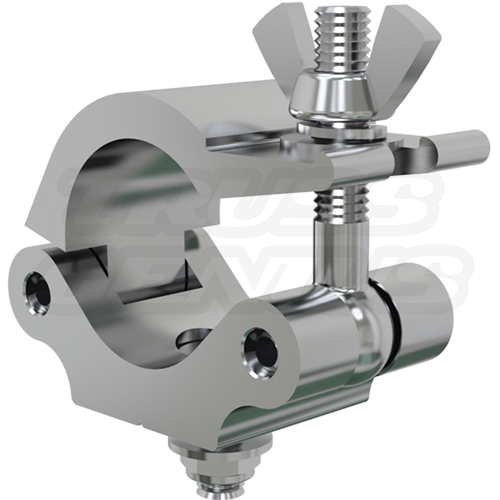

For a fixed pipe size, go with something like below, and feel safe walking under it.

Commonly referred to as a "cheeseboro" or even a Cheese Burger.

About $10

Commonly referred to as a "cheeseboro" or even a Cheese Burger.

About $10

Last edited:

For a fixed pipe size, go with something like below, and feel safe walking under it.

Commonly referred to as a "cheeseboro" or even a Cheese Burger.

About $10

Wouldn't that be a half burger?

Tech_Geek97

Member

can you hang lightweight fixtures horizontally with a c clamp?

I do know of instances where C-clamp type side-arms were used on booms and some doofus used the shin buster arm as a step to re-gel a higher unit with very bad results.

porkchop

Well-Known Member

A C-Clamp is fine for almost all uses that I've ever encountered (with the previously mentioned precautions to avoid marring the truss). If I was going to go to something that wraps completely around like an O-Clamp or a cheeseboro (which BTW I would call a half-coupler) I would look at Mega Claws mostly because the clamp will support the fixture on the beam before the tightening bolt is made. Also they have an actual load rating (first Google search brings up one rated to 1000 lbs.). On the other hand, they are significantly more expensive than any of the other clamps mentioned so far in this thread, around $25 each MSRP, and technicians that don't regularly use this style clamp can find them a bit fiddly (if you flip the latch all the way up and try to take a moving light off the truss you will do nothing but get frustrated, I think it's a "safety" feature).

Sometimes the only way to make the work-site safe if to remove someone, either by firing or self inflicted.

I do know of instances where C-clamp type side-arms were used on booms and some doofus used the shin buster arm as a step to re-gel a higher unit with very bad results.

Sometimes the only way to make the work-site safe if to remove someone, either by firing or self inflicted.

Similar threads

- Replies

- 13

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)