Hello, all - my first post at this most wonderful resource.

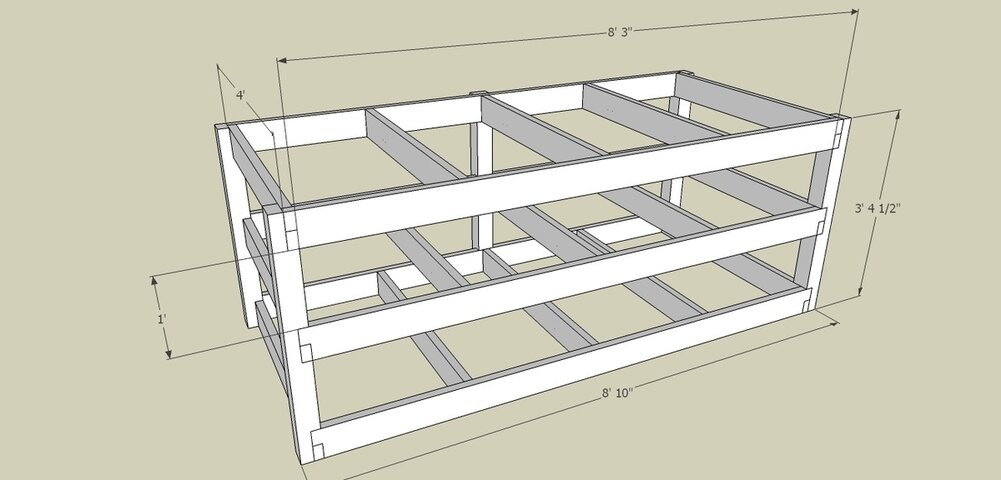

I'm in the planning stages of completely re-designing our school's scene shop over the summer, and one of the things I'd like to include is a new storage unit that can hold sheet goods as well as 18 to 24 Hollywood flats (range of 8 to 12 feet in height). I currently have a couple of wheeled storage racks for this purpose, but they don't take 12-foot flats, they use up a lot of vertical space in their structure, and they aren't designed for the weight of a ton of plywood.

I would like to build something up from the concrete floor of the shop. If anyone has a photo of something they've built, I'd love to see it. I've searched all over the fora here and couldn't find anything useful.

Much appreciation for your help!

M

I'm in the planning stages of completely re-designing our school's scene shop over the summer, and one of the things I'd like to include is a new storage unit that can hold sheet goods as well as 18 to 24 Hollywood flats (range of 8 to 12 feet in height). I currently have a couple of wheeled storage racks for this purpose, but they don't take 12-foot flats, they use up a lot of vertical space in their structure, and they aren't designed for the weight of a ton of plywood.

I would like to build something up from the concrete floor of the shop. If anyone has a photo of something they've built, I'd love to see it. I've searched all over the fora here and couldn't find anything useful.

Much appreciation for your help!

M