I have an Electro Controls Dimmer / Panel Model 720W5E at my school here that I have some questions about.

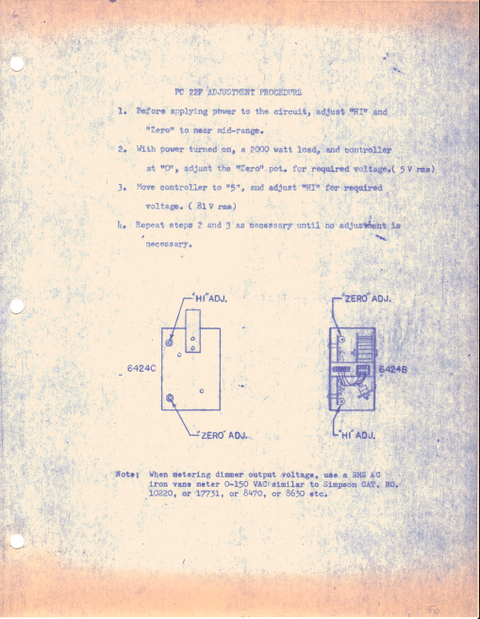

First, does anyone know what sort of control signal the dimmer modules (Model PC 22F, they look like SCR dimmers) take? I'm thinking of building an interface to at least MIDI (easy to work with) or, better yet, DMX for the board.

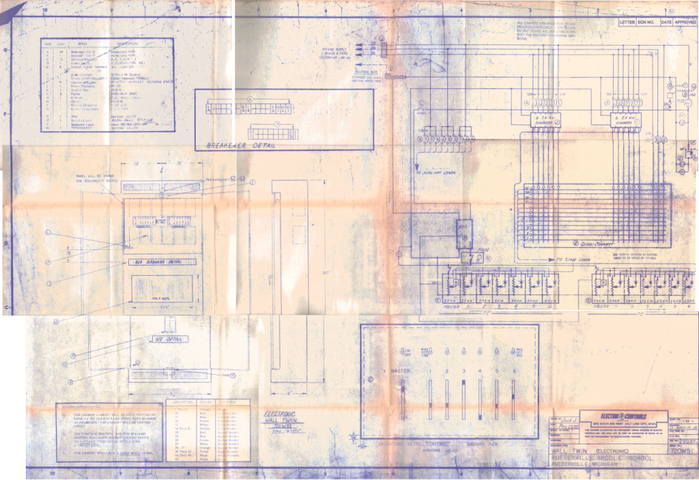

I was able to find a folder with the panel schematics and a short introduction to the board (I've attached the most info I have on the dimmers themselves, sorry for the blurry cell phone pictures, I'll try and get my camera in later) and it looks like it's an analog voltage based input, but I'm not sure (I could hook up an oscilloscope, but I don't want to fry a good DSO).

Unfortunately, I'm working on a zero budget through all this (my own resources limit me to about $100 - $150 total cost), unless it's necessary building repair (sinking fund).

Is it even possible?

Also, 4 of the dimmers don't work at all, and I noticed they're all on the same phase (the panel is 3 phase, wired directly from the building's switchgear in the boiler room, the breaker there is 100A fused). I checked the phase at the dimmer panel and I'm getting some odd results (all from a true-RMS digital multimeter):

- 120v from phase 1 to neutral

- floating from phase 2 to neutral

- 120v from phase 3 to neutral

- ~213v between phase 1 and 3

- 120v between phase 2 and either 1 or 3?

Also, my meter has a non-contact voltage feature (audible) and it sounds like phase 1 and 3 are live, but nothing from phase 2..

what would cause this? is it even fixable? (obviously by a licensed electrician, I'm just curious)

Could the dimmers be broken? (I hope not.. working with only 6 dimmers is a pain)

Just for background. The "stage" (cafeteria + elevated stage) was built in 1973. All the fixtures, raceway, and dimmers are Electro Controls. there's only 30 or so circuits, all the fixtures are par cans, Fresnels, or scoops. The control panel is just sliders and a group master, single scene, so it's kind of restricting as is.

I'd hate to think it, but I'm guessing each whip is asbestos insulated... I've already called the factory representative, who denies ever carrying Electro Controls (too long ago). so I'm pretty much out of directions here...

Any help (or random information for that matter) is appreciated.

First, does anyone know what sort of control signal the dimmer modules (Model PC 22F, they look like SCR dimmers) take? I'm thinking of building an interface to at least MIDI (easy to work with) or, better yet, DMX for the board.

I was able to find a folder with the panel schematics and a short introduction to the board (I've attached the most info I have on the dimmers themselves, sorry for the blurry cell phone pictures, I'll try and get my camera in later) and it looks like it's an analog voltage based input, but I'm not sure (I could hook up an oscilloscope, but I don't want to fry a good DSO).

Unfortunately, I'm working on a zero budget through all this (my own resources limit me to about $100 - $150 total cost), unless it's necessary building repair (sinking fund).

Is it even possible?

Also, 4 of the dimmers don't work at all, and I noticed they're all on the same phase (the panel is 3 phase, wired directly from the building's switchgear in the boiler room, the breaker there is 100A fused). I checked the phase at the dimmer panel and I'm getting some odd results (all from a true-RMS digital multimeter):

- 120v from phase 1 to neutral

- floating from phase 2 to neutral

- 120v from phase 3 to neutral

- ~213v between phase 1 and 3

- 120v between phase 2 and either 1 or 3?

Also, my meter has a non-contact voltage feature (audible) and it sounds like phase 1 and 3 are live, but nothing from phase 2..

what would cause this? is it even fixable? (obviously by a licensed electrician, I'm just curious)

Could the dimmers be broken? (I hope not.. working with only 6 dimmers is a pain)

Just for background. The "stage" (cafeteria + elevated stage) was built in 1973. All the fixtures, raceway, and dimmers are Electro Controls. there's only 30 or so circuits, all the fixtures are par cans, Fresnels, or scoops. The control panel is just sliders and a group master, single scene, so it's kind of restricting as is.

I'd hate to think it, but I'm guessing each whip is asbestos insulated... I've already called the factory representative, who denies ever carrying Electro Controls (too long ago). so I'm pretty much out of directions here...

Any help (or random information for that matter) is appreciated.

![IMAGE_119[1].jpg](https://www.controlbooth.com/data/attachments/2/2849-b47f5f7ac6c66d40a317a9ba3b93e1a7.jpg)

![IMAGE_122[1].jpg](https://www.controlbooth.com/data/attachments/2/2850-1840637ac0f63d0402cd40aa4536ef72.jpg)

![IMAGE_127[1].jpg](https://www.controlbooth.com/data/attachments/2/2854-d2b65908498d861ad656f760a2fb17c2.jpg)

![IMAGE_124[1].jpg](https://www.controlbooth.com/data/attachments/2/2855-b4f0955cf78d9af078d8df85149e11d3.jpg)

![IMAGE_122[1].jpg](https://www.controlbooth.com/data/attachments/2/2856-4dc67d5b3e24c2c353f13e72e956bbea.jpg)