Where on earth do you guys store all these monsters? Doesn't anyone build parallels any more?

I’ve seen one but it had been permanently set open. I’ve never built one.

Where on earth do you guys store all these monsters? Doesn't anyone build parallels any more?

Me! Me! Me! That was the old system back in the day.I dont think too many here have ever seen a parallel, let alone build one.

Me! Me!! Me!!! Too! Too!! Too!!!Me! Me! Me! That was the old system back in the day.

Our current stock risers use triscuits on a knockdown 1x pine frame assembled with 1/4-20 bolts and T-nuts;. The frames bang together pretty quickly but the decks are a bit finicky to align. Coffin locks would be a better option for holding those down. Storage space is at a premium in the venue.

No. We're all out of clinch nail s, animal glue, and dry pigment. Sorry.

Oh wow, how about bronze powder?

I think by definition a leg is in compression.

Doesn't anyone build parallels any more?

You guys are killing me with all these 2x4s. Hem/fir is way too heavy for scenery.

In my carpentry days I built #3 pine 1x6 (5 1/2") frames, 3 (or 5 stiles for dance) w 1/2" CDX. And wood glue - stronger than screws! Compression legs bolted on of course. Easy to carry, stacks for simple steps (6" tall), stores well and not so expensive we couldn't beat them up and build new.

You guys are killing me with all these 2x4s. Hem/fir is way too heavy for scenery.

In my carpentry days I built #3 pine 1x6 (5 1/2") frames

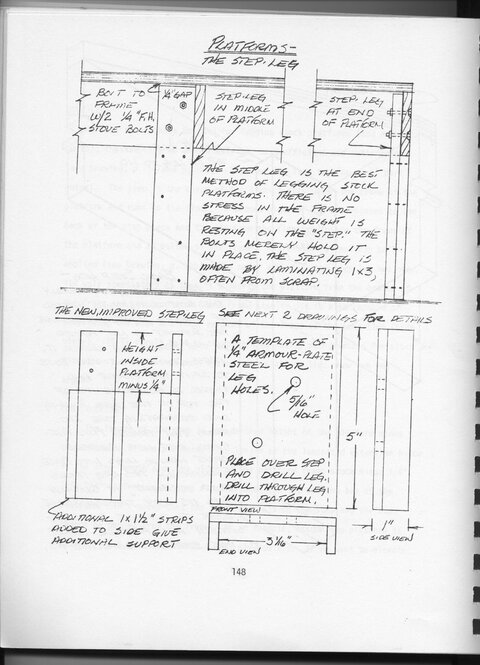

In my scenery-building days I was a firm disciple of Bill Raoul's "Stock Scenery Construction" handbook where everything was made of 1x.

I don’t think the kids could build one if their life depended on it, let alone afford the clear 5/4 stock.I dont think too many here have ever seen a parallel, let alone build one.

@Richard Young @BillConnerFASTC In 1973 we built parallels of 1 foot and less (8") using 3/4" ply and windowing it to reduce weight, create hand-holds and feet. Standard 5/4 stock with glue, clinched nails and corner blocks et al were more economical both material and labor-wise for our 2', 3', 4' and 5' parallels. All tops were 3/4" 4' x 8' ply with corner blocks and were identical. We built at least 8 of each height plus a couple of 4' x 4' and a couple of specially angled units for choral riser set-ups. Fortunately we had a large trap room for convenient storage and soon added dedicated storage / transit dollies.I don’t think the kids could build one if their life depended on it, let alone afford the clear 5/4 stock.

Knee walls ( standard in film construction ) are the next best thing. 2x4 legs and bolts are just stupid amateur night. You can’t level that in anything that could remotely be called a short period of time. And try to do that on an outdoor gig.

I once saw someone rip 3/4 ply into 5 1/4 strips for deck framing, claiming it was far cheaper than #2 pine.

We use essential cookies to make this site work, and optional cookies to enhance your experience.