I don't really understand what you mean by "

adapter" or why you would think one is needed. I have used the pin method to

drop standard

curtains using only the grommets that are installed, objects and

soft goods with

cord loops, solid items with holes drilled in them. The pin method is one of the two most common types of commercial

drop. The other is a clamp

release, which I have also used. The commercial version usually uses one clamp and actuator for each

release point. Most recently I used a shop built, clamp method for a full front curtain

drop much like the video you posted. The fabric was a 30' high x 50' wide, light weight Chiffon and had to fall on top of two performers. Obviously any thing hard or heavy like a

grommet was out of the question. For that I used two hogs-trough sections,

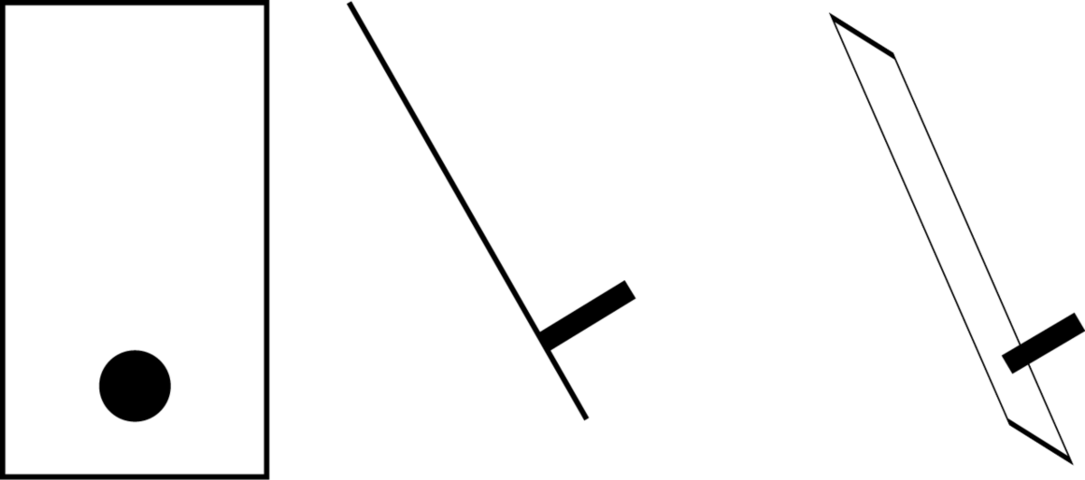

face to

face to form a double stem "T". The "T" was hinged at the top with heavy duty spring loaded hinges that pinched the two stems together. The full length of the lower

edge of each mating "T" was lined with 1" etha-foam rod, split down the middle, so the two rounded faces were pressed together. We roughed up with shiny surface with a little steel wool for "grab" and the fabric was pinched the entire 50' width between the etha-foam pieces. The actuator(s) were 4" x 1" stroke,

pancake cylinders spaced every 10' along the mechanism. The cylinders were attached to the outside

face of one side of the stem. The rods were placed to the inside and poked through a hole drilled in the stem so that when activated, they pushed the stems apart, looking a little like someone's arms and legs when doing a jumping

jack. The air was supplied by a small

portable tank mounted on the

batten and actuated by a

solenoid valve triggered by the SM. One of the advantages of this

system was that should the mechanism fail for any reason to

drop the fabric, a sharp tug at either end would pull the slick fabric out of the clamp and it would continue to fall, like a zipper all the way across. Not the

effect the director really wanted, but acceptable if necessary (never had a failure in three weeks of 8 performances each).

Each method has advantages. The Pin method can be the most economical as one actuator can operate many

release points. The drawback is the object must have a hole in it. Advantage is that the object can never fall prematurely. The clamp method Often (but not always) requires an actuator for each

release point. One advantage is the the clamp can work on any

flat surface. Disadvantage is the object can possibly fall prematurely.

One of the advantages of the pin method is that it "Always" works, not just "Almost Always". "Almost Always" is not acceptable.