Audio guys/gals

I have a idea that I wanted some feedback/WTF are you doing, on.

You see my theatre is wonderful for dance, bands and stage shows. What it's god awful for is orchestra and unamplified sound.

We currently do not have any shells and the space is so **** big (128' x 52' x 66' 8") that the sound goes strait up and not toward the audience at all.

New shells are bit out of our price range so I am looking to do the following:

Build our own.

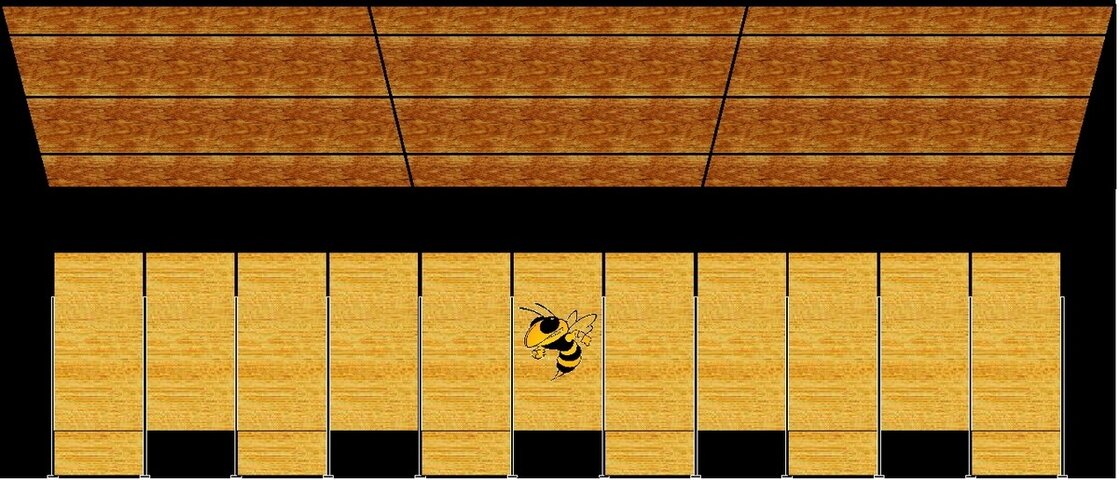

What I am thinking of building is flats with a hard wood or surface on them to surround the musicians and are at least 12ft tall.

Then taking flats of various lengths and flying them on 2 different line sets. This will make a ceiling and force the sound down and out. I will be able to control the angle and the height easily.

My carps assure me this is possible, my riggers can make it safe and my lighting guys will get over their problems at some point.

My question to the audio guys is:

Is this worth doing?

Will this help my sound problems?

Is there anything you all know that would be helpful in this situation?

I am a humble TD who knows very little of the audio world. Can anyone help me out a bit?

Thanks,

GBTimex

I have a idea that I wanted some feedback/WTF are you doing, on.

You see my theatre is wonderful for dance, bands and stage shows. What it's god awful for is orchestra and unamplified sound.

We currently do not have any shells and the space is so **** big (128' x 52' x 66' 8") that the sound goes strait up and not toward the audience at all.

New shells are bit out of our price range so I am looking to do the following:

Build our own.

What I am thinking of building is flats with a hard wood or surface on them to surround the musicians and are at least 12ft tall.

Then taking flats of various lengths and flying them on 2 different line sets. This will make a ceiling and force the sound down and out. I will be able to control the angle and the height easily.

My carps assure me this is possible, my riggers can make it safe and my lighting guys will get over their problems at some point.

My question to the audio guys is:

Is this worth doing?

Will this help my sound problems?

Is there anything you all know that would be helpful in this situation?

I am a humble TD who knows very little of the audio world. Can anyone help me out a bit?

Thanks,

GBTimex