Les

Well-Known Member

So, I had four Applied Electronics wall-mount packs given to me by a church who had purchased them used but never implemented them. Looking inside, I can tell that they were stored in a fairly dirty (and possibly damp) environment. Probably a non-climate controlled storage unit (not unlike the one I have them in now).

Things looks fairly decent and while old, they are are pretty simple so there's not a lot to go wrong. I did find one or two visibly damaged power cubes (thermal damage), but nothing completely terrible. I would like to take them somewhere and have them professionally assessed, but I thought I'd post a few pictures here before I spend any money. If all goes well, I'm hoping to loan them and a bunch of lights I have restored to an arts group in the Austin TX area who is going to be building a temporary space.

There are four of them, 2400x12ch, all in about the same condition.

I think it's safe to say they're analog.

Overall, the inside is decent but needs a good cleaning. Someone installed this fan with some creative wiring. 100% sure that's not factory, but a field upgrade. They appear to have known what they were doing, for the most part, but it is a little messy and questionable:

It is connected to this breaker (bottom right) using what looks like 16 gauge lamp cord:

This unit has power cubes with no visible thermal stress, but they will still need to be checked. Very dirty:

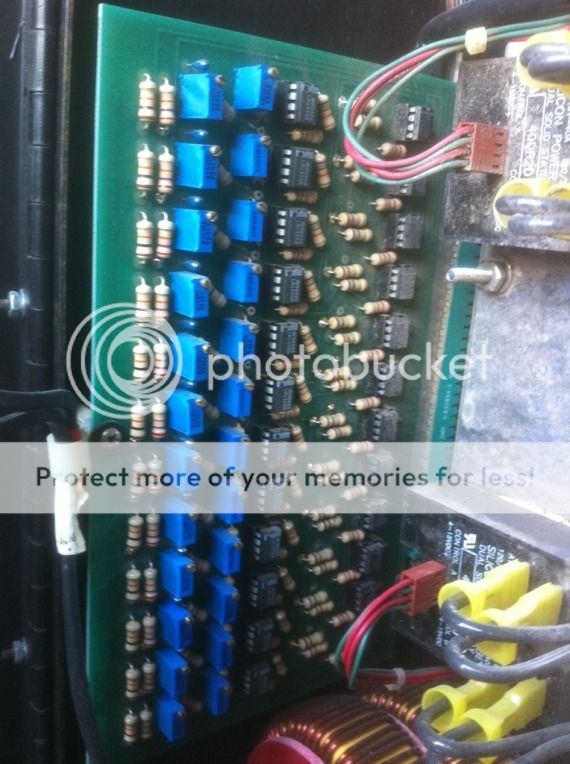

Some control circuitry. Also very dirty and "dry" looking.

One of the packs has an extra set of components. The wire-nutted leads go directly to the terminal strip for the control circuitry. Would this be a DMX-Analog converter, or maybe an interface for a wall station? The bottom white and blue wires are cut -- the white wire is not spliced to the lead going to (or coming from) the SSR.

Notice that one of the power cubes is not like the others. Maybe a relay module or channel set up for a fluorescent/HID load?

More shots of that "extra" board.

What do you guys think? It's 48 channels of 2400 watt dimming, so a lot of me wants to invest in these and make them right again (with professional, in-person help, of course).

Things looks fairly decent and while old, they are are pretty simple so there's not a lot to go wrong. I did find one or two visibly damaged power cubes (thermal damage), but nothing completely terrible. I would like to take them somewhere and have them professionally assessed, but I thought I'd post a few pictures here before I spend any money. If all goes well, I'm hoping to loan them and a bunch of lights I have restored to an arts group in the Austin TX area who is going to be building a temporary space.

There are four of them, 2400x12ch, all in about the same condition.

I think it's safe to say they're analog.

Overall, the inside is decent but needs a good cleaning. Someone installed this fan with some creative wiring. 100% sure that's not factory, but a field upgrade. They appear to have known what they were doing, for the most part, but it is a little messy and questionable:

It is connected to this breaker (bottom right) using what looks like 16 gauge lamp cord:

This unit has power cubes with no visible thermal stress, but they will still need to be checked. Very dirty:

Some control circuitry. Also very dirty and "dry" looking.

One of the packs has an extra set of components. The wire-nutted leads go directly to the terminal strip for the control circuitry. Would this be a DMX-Analog converter, or maybe an interface for a wall station? The bottom white and blue wires are cut -- the white wire is not spliced to the lead going to (or coming from) the SSR.

Notice that one of the power cubes is not like the others. Maybe a relay module or channel set up for a fluorescent/HID load?

More shots of that "extra" board.

What do you guys think? It's 48 channels of 2400 watt dimming, so a lot of me wants to invest in these and make them right again (with professional, in-person help, of course).

Last edited: