Hi all

I know there have been other posts about this. I actually read the one on here related to the same issue I am having however I felt that issue was not exactly the same as mine. Here is a little background on both me and the lighting console. I am not a professional lighting person by any means I am just a volunteer tech director for a theater group in my area so some things are above my skill set. However with the Lee Colortran ENR 96 Dimmer rack I can pretty much work and take care of any issues it has except for the one that I am on here about.

Ok about the Lighting system. The Lee Colortran ENR 96 system I am using was installed in one of the local High Schools in my area. Actually I attend that high school and used the system while I was there. I believe if I remember right the system was installed there around about 1988 or 89 The school did not take very good care of it so and it had to be cleaned out a lot. Flash forward to about 2010. The high school decided to renovate and get all new equipment and so the old was put up for bid. With that in mind I had an old Spectrum Design and Developemt stage pin system that was down to 3 dimmers from 12 do to electrical issues. So with that in mind I placed a bid on the Lee Colortran ENR 96 Dimmer rack and Status 24/48 light board. I won the system and transported it back to the theater that volunteer at. Due to financial issues the system sat there not connected to any power and in a corner of the building till the old one died about 3 years ago. So I went and got the Lee Cortran ENR 96 Dimmer rack installed.

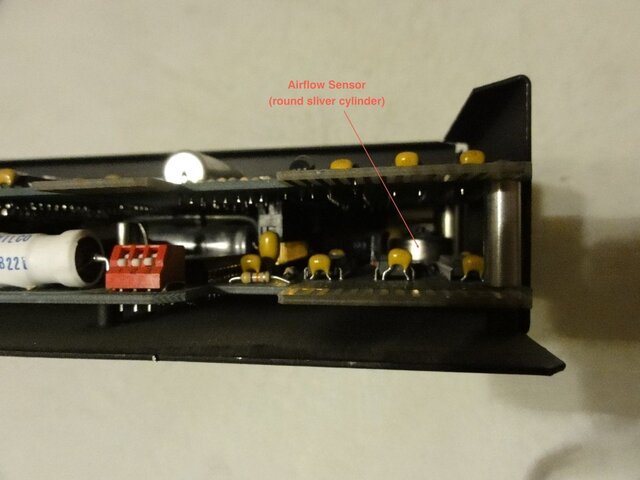

Ok now the issue: The system was working well no problems after I figured out what dimmers corresponded with the patch strip I had installed on the wall next to the rack. After about 2 years of using the system it started acting funny this past summer. If I remove one of the dimmer mods it runs with out an issue. However after I remove 4 or 5 of them it goes in to the airflow mode and shuts down the rack. I use to be able to run the system with just the 6 dimmers I am using along with control mods in as well and it would work just fine. It is been just recently that if I take out more then 4 or 5 dimmers it goes in to air flow mode. Anyone have any ideas on what may be causing this. I clean out the system by vacuuming everything every 3 months so the dust does not get very bad. Also I have a power limitation that I am able only to safely power up 12 dimmers consisting of 6 Dimmer mods. Half of the rack are dud mods that I believe are for helping with air flow and I have about 4 constant mods. Any one have any ideas on my issue and how to fix it

Sorry for the long first Post just felt I needed to give all of the info I could

Thanks

I know there have been other posts about this. I actually read the one on here related to the same issue I am having however I felt that issue was not exactly the same as mine. Here is a little background on both me and the lighting console. I am not a professional lighting person by any means I am just a volunteer tech director for a theater group in my area so some things are above my skill set. However with the Lee Colortran ENR 96 Dimmer rack I can pretty much work and take care of any issues it has except for the one that I am on here about.

Ok about the Lighting system. The Lee Colortran ENR 96 system I am using was installed in one of the local High Schools in my area. Actually I attend that high school and used the system while I was there. I believe if I remember right the system was installed there around about 1988 or 89 The school did not take very good care of it so and it had to be cleaned out a lot. Flash forward to about 2010. The high school decided to renovate and get all new equipment and so the old was put up for bid. With that in mind I had an old Spectrum Design and Developemt stage pin system that was down to 3 dimmers from 12 do to electrical issues. So with that in mind I placed a bid on the Lee Colortran ENR 96 Dimmer rack and Status 24/48 light board. I won the system and transported it back to the theater that volunteer at. Due to financial issues the system sat there not connected to any power and in a corner of the building till the old one died about 3 years ago. So I went and got the Lee Cortran ENR 96 Dimmer rack installed.

Ok now the issue: The system was working well no problems after I figured out what dimmers corresponded with the patch strip I had installed on the wall next to the rack. After about 2 years of using the system it started acting funny this past summer. If I remove one of the dimmer mods it runs with out an issue. However after I remove 4 or 5 of them it goes in to the airflow mode and shuts down the rack. I use to be able to run the system with just the 6 dimmers I am using along with control mods in as well and it would work just fine. It is been just recently that if I take out more then 4 or 5 dimmers it goes in to air flow mode. Anyone have any ideas on what may be causing this. I clean out the system by vacuuming everything every 3 months so the dust does not get very bad. Also I have a power limitation that I am able only to safely power up 12 dimmers consisting of 6 Dimmer mods. Half of the rack are dud mods that I believe are for helping with air flow and I have about 4 constant mods. Any one have any ideas on my issue and how to fix it

Sorry for the long first Post just felt I needed to give all of the info I could

Thanks