You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

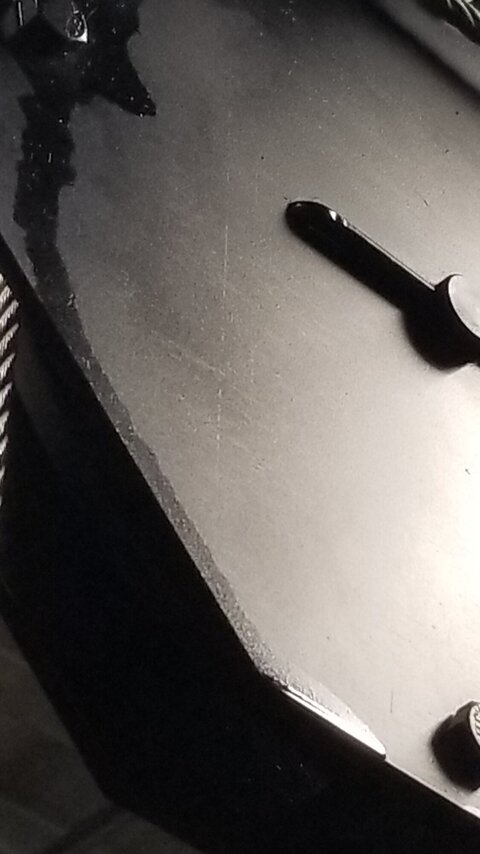

Oil drips from loft blocks

- Thread starterDsmagnussen

- Start date

What Rigger?

I'm so fly....I Neverland.

Hey @egilson1, can I play "what if" for a second? . Any thoughts on the possibility of too much lubricant in the wire rope, and gravity wringing it out at the loft blocks. Gravity compressing the wire rope over the sheave as it sits, when the weather gets warm? The photos kind of look like the lube in question is weeping down the cheek plates.I’ve seen it often during inspections. It’s usually from the grease on/in the bearings breaking down. It’s hard to say if it’s an indication of a problem or not.

Thanks for indulging me.

Everyone listen to Ethan- he is waaaayyyyy more experienced than me.

Hey @egilson1, can I play "what if" for a second? . Any thoughts on the possibility of too much lubricant in the wire rope, and gravity wringing it out at the loft blocks. Gravity compressing the wire rope over the sheave as it sits, when the weather gets warm? The photos kind of look like the lube in question is weeping down the cheek plates.

Thanks for indulging me.

Everyone listen to Ethan- he is waaaayyyyy more experienced than me.

That’s a possibility. Brings up a good story. So when we talk about “aircraft cable” there are predominantly 2 types. The stuff we all buy, and MIL SPEC. That’s the stuff actually used for aviation. It’s lubricated. A lot. If you use mill spec for rigging, you will end up with a LOT of lubricator all over everything on stage. It will ruin your drape, deck, and everything else it comes into contact with. I’ve seen it once. The installer’s supplier substituted it on the order, no one noticed and they installed 30 or so line sets using it. Needles to say, all new lift lines, drape, and sprung floor were installed.

that being said, the amount in the posted pictures is minimal in comparison.

Ethan

Dsmagnussen

Member

Thank you. Have you ever heard/seen a situation where line sets sit idle for a long time and this occurs? This has been with us for many years, and as I stated, it seems to only happen in the summer when the temps in the loft get higher. We fly less in the summer as well. Just a little mystery.I’ve seen it often during inspections. It’s usually from the grease on/in the bearings breaking down. It’s hard to say if it’s an indication of a problem or not.

Lasermike

Well-Known Member

Going out on a limb here but I’d guess that the grease is breaking down due to age and the higher temperatures of summer.

Old school grease is oil thickened with a soap base. Usually lithium or molybdenum. Over time, the soap breaks down and the oil “leaks” out. I don’t think synthetics break down in the same way but then I’m not a chemist nor have I slept in an Holiday Inn Express lately.

Michael

Old school grease is oil thickened with a soap base. Usually lithium or molybdenum. Over time, the soap breaks down and the oil “leaks” out. I don’t think synthetics break down in the same way but then I’m not a chemist nor have I slept in an Holiday Inn Express lately.

Michael

Dsmagnussen

Member

Would the old school grease have been in use 14 years ago? Or is it still used? This system was put in in 2006, and a lot of things were changing around that time. Just throwing questions to the wind.Going out on a limb here but I’d guess that the grease is breaking down due to age and the higher temperatures of summer.

Old school grease is oil thickened with a soap base. Usually lithium or molybdenum. Over time, the soap breaks down and the oil “leaks” out. I don’t think synthetics break down in the same way but then I’m not a chemist nor have I slept in an Holiday Inn Express lately.

Michael

Lasermike

Well-Known Member

In this case, old school implies anything that isn’t synthetic. I don’t know if synthetics break down the way that non synthetics do but they are less common in everyday use so it’s much more likely the blocks are lubed with regular old grease which can and does break down.

The only real fix would be to flush out the old grease and relube. I can’t say what type of grease should be used, I’d follow the manufacturers guidelines.

Also, mixing lithium and moly greases causes them to break down fairly quickly so if things were fine then the dripping started shortly after someone PM’d the blocks, I’d suspect the wrong grease was used.

Michael

The only real fix would be to flush out the old grease and relube. I can’t say what type of grease should be used, I’d follow the manufacturers guidelines.

Also, mixing lithium and moly greases causes them to break down fairly quickly so if things were fine then the dripping started shortly after someone PM’d the blocks, I’d suspect the wrong grease was used.

Michael

Rossclan

Member

Hey Doug--Dave and I were just discussing this and we hit all the same points that the others have pointed out as possibilities. I have some questions for you. Do all of the loft blocks do this or just some of them? Do you have a feel for how hot it gets in your loft? The photo of the side plate with the oil dripping down clips out the top part of the plate. This is the photo that makes this a bit puzzling to us because the oil is dripping down the outside edge of the side plate. It seems to me that if the bearing grease is breaking down and leaking from the bearing in a sheave that has not been operating for a while, the drip run down the center of the sheave or the center of the side plate. The fact that it's on the outside edge of the plate made me think that it was the cable as @egilson1 described; however, if that mil-spec cable carries as much lube as noted, then I can't imagine it's mil-spec or you'd see oil everywhere. The only other thought I had is if someone, at some point in time, decided to manually lube the cable. As silly as this sounds, I've heard of people doing this thinking that it should be part of regular maintenance. If you haven't already, I think you need to get up close and personal with those blocks when they start dripping (before anyone moves anything) to determine where the oil is coming from. But, like Ethan said, just because a bearing is leaking grease that has broken down with age (I have some in a grease gun in basement that did this. Left a nice puddle for me), does not necessarily mean that there's a problem. If the sheave has some wobble or is making grinding noises, then you definitely have a problem. Otherwise, it's more nuisance than problem--for now.

Dsmagnussen

Member

No, I wish I could blame a overeager student for greasing the blocks, but that has not happened. And the lines have never shown any oil coming out of them. I will take some more pics and post them, but I think we are all going down the same path. I think it is the grease breaking down. I have never done a temp. log for the loft, so that is now going to become a thing. My hope is that once we get into the cooler fall temps, this will start to go away. If it does not, and we are not doing events (or moving lines) then it would lead me more toward inactivity keeping the grease for being "mixed" so then it starts to separate? No wobbles, or strange noises from the blocks. This system is 14 years old and is still smooth. (insert plug for Secoa here) Though I might go to them for this grease issue......Hey Doug--Dave and I were just discussing this and we hit all the same points that the others have pointed out as possibilities. I have some questions for you. Do all of the loft blocks do this or just some of them? Do you have a feel for how hot it gets in your loft? The photo of the side plate with the oil dripping down clips out the top part of the plate. This is the photo that makes this a bit puzzling to us because the oil is dripping down the outside edge of the side plate. It seems to me that if the bearing grease is breaking down and leaking from the bearing in a sheave that has not been operating for a while, the drip run down the center of the sheave or the center of the side plate. The fact that it's on the outside edge of the plate made me think that it was the cable as @egilson1 described; however, if that mil-spec cable carries as much lube as noted, then I can't imagine it's mil-spec or you'd see oil everywhere. The only other thought I had is if someone, at some point in time, decided to manually lube the cable. As silly as this sounds, I've heard of people doing this thinking that it should be part of regular maintenance. If you haven't already, I think you need to get up close and personal with those blocks when they start dripping (before anyone moves anything) to determine where the oil is coming from. But, like Ethan said, just because a bearing is leaking grease that has broken down with age (I have some in a grease gun in basement that did this. Left a nice puddle for me), does not necessarily mean that there's a problem. If the sheave has some wobble or is making grinding noises, then you definitely have a problem. Otherwise, it's more nuisance than problem--for now.

We had what I thought was the same problem. I'd come in and notice grimy drips on the deck. Looked like oil, but didn't really smell like much. Long story short, our AC has been on the fritz and running non stop. This created a literal cloud layer in our fly loft. I climbed to the loading bridge, to start training our new batch of HS techs earlier last week and the temp difference between the lock rail (ours is elevated) and the loading bridge was easily 20 degrees. That's not unusual, but what was unusual was the moisture level. I can only assume that because of the AC running nonstop, the cold air pushed the warm moist air up and it just overaccumulated during the 5 months we didn't really do any shows.

We had water on every piece of steel up there and it was quite literally raining down on the stage. Looked just like your pictures. I've got a box fan setup now, blasting upwards and it was enough to recycle the wet air down, but it's a mess. There's mold growing on our orchestra clouds.

We had water on every piece of steel up there and it was quite literally raining down on the stage. Looked just like your pictures. I've got a box fan setup now, blasting upwards and it was enough to recycle the wet air down, but it's a mess. There's mold growing on our orchestra clouds.

Ted jones

Well-Known Member

Strangely enough, I saw this today. In this case, a 20 to 30ish year old Secoa install in IL. Oil is dripping onto the deck. Safety problem #1- Slippery spots on deck. It's not true aircraft cable. No more cable lube than anywhere else AND Secoa wouldn't have spent the money unless it was specified with certification. Apparently the summer temps get over 100 in the grid on weekends when the AC is off.

The leakage is from the center of the blocks, under the shafts which leads me to look at bearings. They probably are not sealed and are probably roller bearings. My problem with parts of the grease dripping out with heat is that the lubricant is missing part of it's makeup and may be drying up. Then these bearings are essentially becoming unlubricated and probably collecting dust, which may further dry them out.

What I told my potential customer is that the blocks will not catastrophically fail immediately from this. They will fail by making the sets harder to operate and eventually there will be grinding noise. (I have a sample block where the bearings failed and cut half way thru the shaft before the customer noted the noise and asked me to look at it. It had been a couple of years after the bearing failure.)

The above said, if its from the cable, probably not much of an issue, given the amount of use in a theater. Assuming yearly inspections are made, the frays that will appear from dried cable will facilitate replacement. However, if it is bearing lube, then the lifespan of the system will be greatly reduced as the sets will be come more and more difficult to move.

As an aside: We don't want anything to do with opening up blocks, lubing them and reinstalling them. As soon as we open them and reassemble them, we assume the liability for 20/30 year old blocks made by a company that no longer exists. So replacement would be the only option from us.

The leakage is from the center of the blocks, under the shafts which leads me to look at bearings. They probably are not sealed and are probably roller bearings. My problem with parts of the grease dripping out with heat is that the lubricant is missing part of it's makeup and may be drying up. Then these bearings are essentially becoming unlubricated and probably collecting dust, which may further dry them out.

What I told my potential customer is that the blocks will not catastrophically fail immediately from this. They will fail by making the sets harder to operate and eventually there will be grinding noise. (I have a sample block where the bearings failed and cut half way thru the shaft before the customer noted the noise and asked me to look at it. It had been a couple of years after the bearing failure.)

The above said, if its from the cable, probably not much of an issue, given the amount of use in a theater. Assuming yearly inspections are made, the frays that will appear from dried cable will facilitate replacement. However, if it is bearing lube, then the lifespan of the system will be greatly reduced as the sets will be come more and more difficult to move.

As an aside: We don't want anything to do with opening up blocks, lubing them and reinstalling them. As soon as we open them and reassemble them, we assume the liability for 20/30 year old blocks made by a company that no longer exists. So replacement would be the only option from us.

We had what I thought was the same problem. I'd come in and notice grimy drips on the deck. Looked like oil, but didn't really smell like much. Long story short, our AC has been on the fritz and running non stop. This created a literal cloud layer in our fly loft. I climbed to the loading bridge, to start training our new batch of HS techs earlier last week and the temp difference between the lock rail (ours is elevated) and the loading bridge was easily 20 degrees. That's not unusual, but what was unusual was the moisture level. I can only assume that because of the AC running nonstop, the cold air pushed the warm moist air up and it just overaccumulated during the 5 months we didn't really do any shows.

This happens in my theater. First thing I thought when I started reading the thread.

Dsmagnussen

Member

Nope not every block. And now that the temps have fallen, it has stopped. So I am back to measuring the temp difference in the loft, and adding a fan to cycle the air, I guess?

Dsmagnussen

Member

Thanks for the info. I will keep my eyes on them as we go along. I am up there at least a couple a of times a semester just to check on things anyway.Strangely enough, I saw this today. In this case, a 20 to 30ish year old Secoa install in IL. Oil is dripping onto the deck. Safety problem #1- Slippery spots on deck. It's not true aircraft cable. No more cable lube than anywhere else AND Secoa wouldn't have spent the money unless it was specified with certification. Apparently the summer temps get over 100 in the grid on weekends when the AC is off.

The leakage is from the center of the blocks, under the shafts which leads me to look at bearings. They probably are not sealed and are probably roller bearings. My problem with parts of the grease dripping out with heat is that the lubricant is missing part of it's makeup and may be drying up. Then these bearings are essentially becoming unlubricated and probably collecting dust, which may further dry them out.

What I told my potential customer is that the blocks will not catastrophically fail immediately from this. They will fail by making the sets harder to operate and eventually there will be grinding noise. (I have a sample block where the bearings failed and cut half way thru the shaft before the customer noted the noise and asked me to look at it. It had been a couple of years after the bearing failure.)

The above said, if its from the cable, probably not much of an issue, given the amount of use in a theater. Assuming yearly inspections are made, the frays that will appear from dried cable will facilitate replacement. However, if it is bearing lube, then the lifespan of the system will be greatly reduced as the sets will be come more and more difficult to move.

As an aside: We don't want anything to do with opening up blocks, lubing them and reinstalling them. As soon as we open them and reassemble them, we assume the liability for 20/30 year old blocks made by a company that no longer exists. So replacement would be the only option from us.

Dsmagnussen

Member

Mine is grease. That bites! When I was a contractor, I went into a theatre that had flown their curtains for the summer and the condensation level was about 5 feet up from the bottom of each curtain. They had rivulets and stalactites of flameproofing hanging off of them in the fall. Had to replace all of the softgoods.We had what I thought was the same problem. I'd come in and notice grimy drips on the deck. Looked like oil, but didn't really smell like much. Long story short, our AC has been on the fritz and running non stop. This created a literal cloud layer in our fly loft. I climbed to the loading bridge, to start training our new batch of HS techs earlier last week and the temp difference between the lock rail (ours is elevated) and the loading bridge was easily 20 degrees. That's not unusual, but what was unusual was the moisture level. I can only assume that because of the AC running nonstop, the cold air pushed the warm moist air up and it just overaccumulated during the 5 months we didn't really do any shows.

We had water on every piece of steel up there and it was quite literally raining down on the stage. Looked just like your pictures. I've got a box fan setup now, blasting upwards and it was enough to recycle the wet air down, but it's a mess. There's mold growing on our orchestra clouds.

Dsmagnussen

Member

Also, Dave is my hero!!No, I wish I could blame a overeager student for greasing the blocks, but that has not happened. And the lines have never shown any oil coming out of them. I will take some more pics and post them, but I think we are all going down the same path. I think it is the grease breaking down. I have never done a temp. log for the loft, so that is now going to become a thing. My hope is that once we get into the cooler fall temps, this will start to go away. If it does not, and we are not doing events (or moving lines) then it would lead me more toward inactivity keeping the grease for being "mixed" so then it starts to separate? No wobbles, or strange noises from the blocks. This system is 14 years old and is still smooth. (insert plug for Secoa here) Though I might go to them for this grease issue......

Similar threads

- Replies

- 24

- Views

- 2K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)