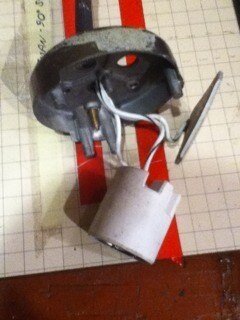

Current Altman lamp sockets are as with I believe all brands of P-28s lamp sockets -

Fresnel or old school radial

Leko lamp

socket made differently at this

point. There has been a mounting screw change that don’t fit the old gear in where the screws mounting it don't match up, also an O.D. to the

socket that won’t always fit inside older fixtures in being larger. This is fact in just ordered some from

Altman to confirm amongst other brands of

socket Bryant, Bender, Ushio

etc to confirm. Other sockets that should be a direct replacement are not available any longer.

Meaning, while the lamp

socket type is available from many sources, how they mount as a standard in holes to fit have changed, as with the O.D. of the

socket now larger. That O.D. of the

socket in some instances might become a problem in

fitting in close tolarances for really old gear, otherwise, just spin the lamp

socket 180 degrees,

mark and re-tap the plate for the new lamp

socket mounting in working again.

This for new’ replacement sockets. Beyond steel wool, I believe I have presented many times on tips and steps to refurbish old P-28s lamp sockets. Believe I have about a 90% ratio in this saving of this specific lamp

base type as long as all advice is followed. We are also talking about well over a hundred of this

base style I have re-surfaced in making viable again and into the hundreds of the range I have saved from... gee bad

base. Than beyond that, cracked

porcelain makes for parts viable to another with a good one. Made up a few viable lamp sockets by way of spare parts also.

On the lamps used, shouldn't make a difference if the lamp

socket is good, spring tension is good as with the wiring - though a more

point source of contact could be debated as opposed to a more plate source if the solder weld isn't more so the drect contact in that plate not mattering.

Can remember some DC bayonet bases with solder conctacts that were a problem also in that solder contact was a source of the problem. Solder literally melted away from the lamp

socket in not providing a good connection. Fan or not of the beade contact, it's not persay better than plate that often isn't it also.