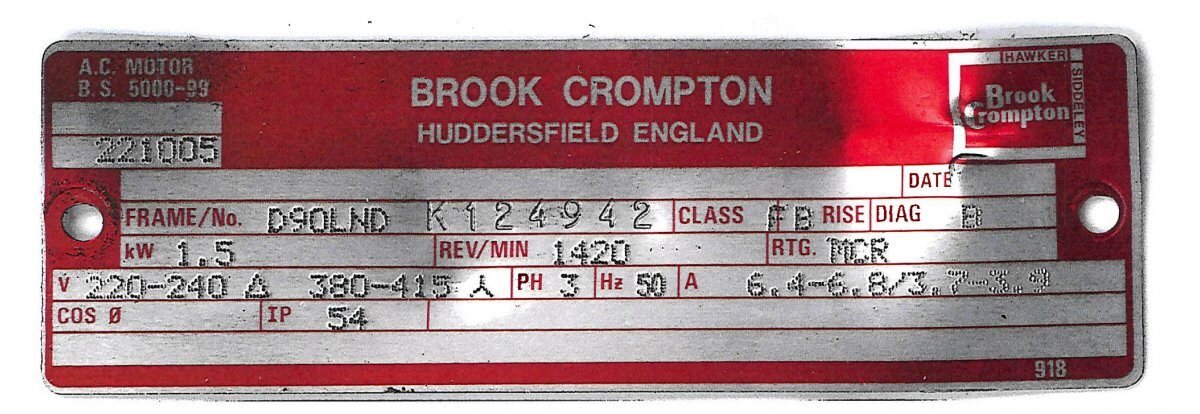

I can think of three ways to deal with the frequency difference:

1. Replace the motor with a 60 Hz one of the same frame type, horsepower, and RPM.

2.

Power it from a diesel generator

3. Use a frequency converter.

Option 1 ignores part of the problem. The other consideration is the hydraulics control

system. It has to be powered properly, too. The

power supply, hydraulic pump, and controls all need to be looked at together

as a system. Overlooking a detail could be catastrophic.

Options 2 and 3 could resolve all of the issues. For option 2, the trick will be finding a generator that will do it. In the days of mechanical governors and simple

voltage regulators, this was fairly easy. Modern generator controls are often too smart to allow 50 Hz at 415 V, unless designed for it. There probably are generators available for this, just not very common. You will need to find a vendor familiar with this. Unless they do it often, I would ask to see a

unit under load at 415 / 50 before committing.

Option 3 is viable but expect a large, heavy, and expensive device. There are both mechanical (motor-generator) and sold state (electronic) frequency converters. Heat and noise will be considerations for both types. If operated in an enclosed space for long periods, ample

HVAC will be required. Be sure the vendor knows that the converter has to start a hydraulic pump, because the starting

current is an important factor.

Frankly, I think the touring company is putting too much on your shoulders by expecting to just bring their equipment in and

power it up. It seems to me that they need to bring equipment designed to operate in North America.

There is more to this than can be resolved in this forum. I assume there is significant money riding on this. If so, hire an electrical engineer with some expertise in this, and let him or her sort it all out.