Hey everyone,

I'm designing a set for Lost in Yonkers, it's a 16'x12' free-rotating platform made up of 6 stock 4'x8' platforms coffin locked together. Each smaller platform will have 6 ball casters (part 5674K57 over at McMaster) to take the weight of the whole set, which I calculate to be around 1300 lbs. My question is basically: will it rotate? If we have 4 stage hands (your average college student) pushing it, do you think we could do a 180 degree turn in a reasonable amount of time?

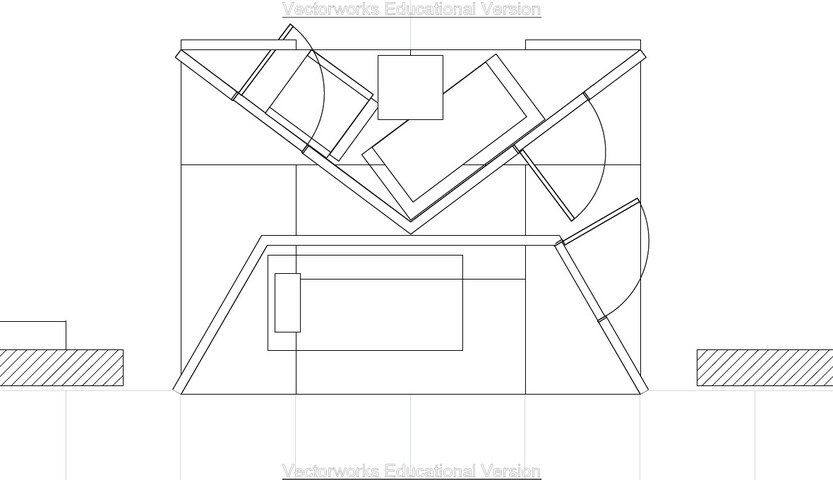

I've attached a ground plan for reference. It has two rooms, a sofa, bunkbed, side table, and two dining room chairs.

Thank you so much in advance!

I'm designing a set for Lost in Yonkers, it's a 16'x12' free-rotating platform made up of 6 stock 4'x8' platforms coffin locked together. Each smaller platform will have 6 ball casters (part 5674K57 over at McMaster) to take the weight of the whole set, which I calculate to be around 1300 lbs. My question is basically: will it rotate? If we have 4 stage hands (your average college student) pushing it, do you think we could do a 180 degree turn in a reasonable amount of time?

I've attached a ground plan for reference. It has two rooms, a sofa, bunkbed, side table, and two dining room chairs.

Thank you so much in advance!

Attachments

Last edited by a moderator: