So I promised that I would update this thread after the show was complete, so here it is.

Some Pictures Here

So as it turns out, everything worked fairly well and as expected. Everything was durable enough so that no repairs were needed. The big dresses and the lightning bolts (

RGB LED tape powered via a custom 12V

shield) had the biggest pop, as expected due to sheer light output. Everything was still visible from the long distances required by the show, but those two units definitely stood out more. Luckily we did not have much rain on this outdoor show, so I cannont really say how waterproof that the units were, but I think that we managed a good balance between access and durability. For some of the units, we encased them in an

acrylic box as they were in more contact with the dancers as they moved around. In terms of the timings on the lighted choreography, having the actors turn them on worked with mixed results, as some costumes were more programmed or patterned to the music than others; however, as we were dealing with 12-18 year olds operating the devices with all of 2 rehearsals, some were closer than others. In some cases, we were within 0.5 seconds in the

pattern which was better than expected.

One timing issue that we did not encounter was the differential in the internal clocks of the

arduino. Even though two would be powered on at the same time, from the same

switch and battery pack, after a period of 2 minutes, a difference in

pattern could be detected. We do not know exactly where this issue comes from, but suspect that it could be helped by an external clock on the device.

Also included in this project which was a late development, we incoporated 12V

LED RGB strips into costumes, (which are the lightning bolts in the pictures) via another custom

bit, that is capable of driving two in-dependant strips of LEDS. These are considered analogue

LED strips as they change the entire strip one color or another, rather than individual

RGB control via bit-shifting. They are mounted to a piece of mirrored plexi and then covered with a triagular piece of acrylic, cut to lightning

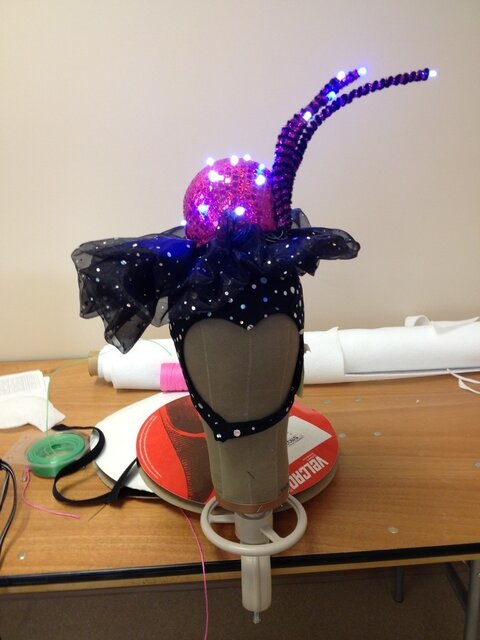

bolt shape. They were also inserted into

clear plastic tubing, which was covered in a semi transparent fabric to give a really cool

effect as the strip spiralled around a hat.

What we learned from the project:

More time and budget would be nice...

Ribbon Cable is your friend as it makes co-ordinating wires and individual LEDs much easier

There are many different evolving technologies out there. LEDs are being developed on a weekly scale, Micro-controllers are open source

Open source technology can be utilized very easily

Sometimes custom parts are required to save time and money as well as get the required

effect - 100 hours soldering or 5 hours of an engineer?

There are people interested in learning about these developments, so share your knowledge to outside groups and other micro-controller groups

Until next time.

Ps. Should I post links to the parts that were developed when they hit the internet?

I was also the rigging intern on the show with HAFE, which was an amazing experience in itself.