You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fixture Attachment: Unistrut

- Thread starterchadgreen

- Start date

That is a " Boingy Nut " or a Uni-strut nut. not uncommon, extremely secure as long as it's installed properly. The Part that you might think is missing is the unistrut itself, The nut goes into the open side of the channel then cams so that the dimples in the nut line up with the rounded over ends on the inside of the channel. The spring adds tension so that you have to slightly lift on the loadto slide the nut back and forth in the channel. Unistrut fixtures can be used in almost any oreintation which is what makes them very cool. If you don't know what you're doing, if you loosen them too much or start really reffing on them you can have issues develope like the nuts comming loose of the track or getting the nut jammed in the track.

From the wiki entry Unistrut:I would like a brief primer on what this is and why someone thought it was a good idea. ... Is it missing something? Is it really a pain to work with? What is it commonly called? ...

City Theatrical has a line of devices to make hanging from Unistrut less painful: Track Tamers.The use of Unistrut-type mounting devices for lighting fixtures divides into two categories: the ambivalents who tolerate it, and those who despise it and will use it only after exhausting every other option.

Why it was/may be/is a good idea:

1. In low ceiling venues, it gains you a couple of inches of height, over a suspended 1.5" pipe and C-clamps.

2. Empty strut, whether surface mounted and painted the same as the ceiling, or recessed into the ceiling, is less visually disturbing than an empty pipe hanging down. Thus Unistrut is often found in hotel ballroom s:

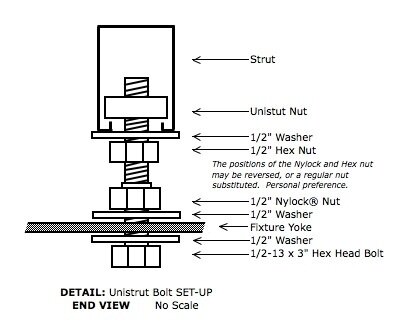

A word of advice: try to use only 1/2"-13 nuts and bolts. While slightly more expensive than 1/4" or 3/8", they are stronger and more compatible with standard lighting hardware (same yoke bolt as a C-Clamp). Oh, and don't forget the washers (especially important when using less than 1/2" bolts); one under the yoke and one under the track.

EDIT: I see that the fixture in one of your photos is an Electro Controls. Do not confuse standard C-channel strut hardware with the Electro Controls'-specific "channel mount". They are similar, but incompatible. See the thread: Electro Controls "Channel Mount" connector strips .

Last edited:

In concept I like the City Theatrical Track Tamer, but the reality is the things are very expensive at approx. $30 ea, as opposed to a standard nut at about $5 ea. ?. Thus I'm not buying the Tamer any time soon, what with 100 units to hang.

Uni-Strut and all it's derivatives (Kindorf, Versa-Bars, Channel Steel, etc...) should be banned from theatrical usage, is my opinion. I have seen way too many students as well as experienced pro's struggle with getting the nut to seat, all while holding a 25lbs stage light tight to a track.

Derek has outlined some of the advantages, and in truth I do use it and in the application below I have Kindorf ( a trade version) in use, using 1-1/2" OD steel pipe would be a PITA, thus the Kindorf.

Attached photo of an Altman 4.5" zoom ellipsoidal hanging from a piece of channel steel in a custom steel dance lighting tower. The towers are 74" high x 18" wide x 30" deep and can hold 5 units pre-hung and cabled. This is a variation on the aluminum versions as (possibly) invented buy Steve Terry way back at Production Arts for a tour of "Dancin. Many dance companies use similar aluminum versions. Mine have welded-in horizontal channel steel with add'l verticals that can move in/out of the tower (to accommodate different fixtures and scrollers), as well as the horizontal fixture bars being vertically adjustable. I recently installed permanent "studs" - I.E. 1/2" bolts for the fixtures to mount on as installing the ****ed nut was impossible when you can't swivel the fixture 90 degree's. The fixture now mounts on the studs.

Uni-Strut and all it's derivatives (Kindorf, Versa-Bars, Channel Steel, etc...) should be banned from theatrical usage, is my opinion. I have seen way too many students as well as experienced pro's struggle with getting the nut to seat, all while holding a 25lbs stage light tight to a track.

Derek has outlined some of the advantages, and in truth I do use it and in the application below I have Kindorf ( a trade version) in use, using 1-1/2" OD steel pipe would be a PITA, thus the Kindorf.

Attached photo of an Altman 4.5" zoom ellipsoidal hanging from a piece of channel steel in a custom steel dance lighting tower. The towers are 74" high x 18" wide x 30" deep and can hold 5 units pre-hung and cabled. This is a variation on the aluminum versions as (possibly) invented buy Steve Terry way back at Production Arts for a tour of "Dancin. Many dance companies use similar aluminum versions. Mine have welded-in horizontal channel steel with add'l verticals that can move in/out of the tower (to accommodate different fixtures and scrollers), as well as the horizontal fixture bars being vertically adjustable. I recently installed permanent "studs" - I.E. 1/2" bolts for the fixtures to mount on as installing the ****ed nut was impossible when you can't swivel the fixture 90 degree's. The fixture now mounts on the studs.

Where I work, we will take two of these, 7 inch Mega-Airwall Hanger, cheeseburger them to lengths of aluminum sched. 40, and hang Source 4's/Mac 500's off of that.

One of our spaces was real small with low ceilings and had a lot of unistrut struts running in the back half of the stage. I've actually found them fairly easy to work with but then again it could just be where we were using them and the fact that we didn't use them much with lights. They work great on bent aluminum rods to bolt scenery pieces and often just served as some back up support. Disliked hanging lights on the struts but for strengthening pieces and traditional japanese puppetry playboards/projection/shadow screen, it was great.

Try 85¢ each:...as opposed to a standard [spring] nut at about $5 ea.

Superstrut 1/2 in. Channel Spring Nuts (5-Pack) - ZA100 1/2EG-10 at The Home Depot , plus the 1/2"13 bolt and washers, of course.

Many have found that using a longer bolt and extra nuts makes life easier.

And perhaps throw in a split lock washer or two.

Last edited:

jglodeklights

Well-Known Member

Horror story about unistrut- the TD or three ago at my University before the current one had no idea how to weld and as such hid the stick welder (they now still have that along with the two MIG welders), and almost all the sets required construction of a material stronger than wood for the space that structural support needed to exist in. The shop manager while I was there, who had been a graduate student during that period, recounted to us making odd cuts of unistrut over and over that were joined together in typical fashion for it. That means a pain in the ass. Having attached lighting units to it before, I would only do it if they are not gonna move for a while.

soundlight

Well-Known Member

I am quite partial to the Light Source "Uni Bolt", also known by its part number UB2B (MSRP: $24.95).

It's a glorious little device that allows you to quickly and easily reposition fixtures in Unistrut. While I'd use standard strut nuts for fixtures that will be permanently installed, I like the UB2B since it can be repositioned very easily by hand.

It's a glorious little device that allows you to quickly and easily reposition fixtures in Unistrut. While I'd use standard strut nuts for fixtures that will be permanently installed, I like the UB2B since it can be repositioned very easily by hand.

Last edited by a moderator:

MPowers

Well-Known Member

Strut and the various hardware that goes with it are all just tools of the trade. Used properly in the right place and time, it is invaluable. Used in the wrong way and in the wrong place it is worse than a disaster.

Strut is not a good general purpose hanging structure. Unlike good ole standard "pipe" it takes a short learning curve to adjust, it isn't just "hook and clamp". IMHO the City theatrical Track Tamer and the Light Source UB2B are the only reasonable method/hardware available on today's market. If strut is what you have to deal with, stop whining and figure out how to use it.

As Derek pointed out, it is extremely useful in "finished" venues like ball rooms, casinos, show rooms and the like. A recent install at a casino ballroom/stage is a case in point. The room design with coffered ceilings and ornate structure did not provide a position to front light the stage apron downstage of the curtain. They did not want a bunch of pipe and stage lights hanging from the ceiling and around the 12' diameter chandeliers. The solution was strut, flush to the underside of the ceiling, powder coated to match the off white ceiling color. The track tamers saved about 4" of space and were a clean sharp look, unlike a "C" clamp. The track tamers were powder coated the same and the source 4 ERS were also custom color to match. Gel frames, safety cables, the whole she-bang, custom color. One of the little known accessories for strut is paintable plastic strips that click in place to cover the slot. The end result was that 16 S4 19 degree ERS are in plain sight but virtually invisible unless you actually look up and try to see them. Pipe and "C" clamps, even powder coated could not have blended in so nicely.

IMHO, if you have a situation where the instruments are put up and taken done often, strut is not a best choice. If you have a set-up where the units are in place for extended periods of time and moved little or rarely, and appearance is important, then strut is a good option to consider.

Strut is not a good general purpose hanging structure. Unlike good ole standard "pipe" it takes a short learning curve to adjust, it isn't just "hook and clamp". IMHO the City theatrical Track Tamer and the Light Source UB2B are the only reasonable method/hardware available on today's market. If strut is what you have to deal with, stop whining and figure out how to use it.

As Derek pointed out, it is extremely useful in "finished" venues like ball rooms, casinos, show rooms and the like. A recent install at a casino ballroom/stage is a case in point. The room design with coffered ceilings and ornate structure did not provide a position to front light the stage apron downstage of the curtain. They did not want a bunch of pipe and stage lights hanging from the ceiling and around the 12' diameter chandeliers. The solution was strut, flush to the underside of the ceiling, powder coated to match the off white ceiling color. The track tamers saved about 4" of space and were a clean sharp look, unlike a "C" clamp. The track tamers were powder coated the same and the source 4 ERS were also custom color to match. Gel frames, safety cables, the whole she-bang, custom color. One of the little known accessories for strut is paintable plastic strips that click in place to cover the slot. The end result was that 16 S4 19 degree ERS are in plain sight but virtually invisible unless you actually look up and try to see them. Pipe and "C" clamps, even powder coated could not have blended in so nicely.

IMHO, if you have a situation where the instruments are put up and taken done often, strut is not a best choice. If you have a set-up where the units are in place for extended periods of time and moved little or rarely, and appearance is important, then strut is a good option to consider.

Cashwalker

Member

About 7 years ago, my venue, a church social hall needed some means to wall-mount the front-light fixtures. A member of the vestry suggested strut, and was willing and able to do the installation. He mounted a 5 foot length right onto the concrete wall with special epoxy-secured-bolts. We then took two sections of strut 2 feet long, bolted back-to-back and bolted on angle brackets top and bottom. Each vertical supports 2 arms. The top arm has a fresnel and a leko top-mounted, the bottom arm has 2 leko's, one top-mounted and one bottom-mounted.

I also dropped a couple 10-foot lengths of thin strut (.75", I think as opposed to the 1.5" that's on the walls) just behind the curtain track, where I hang fresnels. From this strut, I don't bother with inserting the strut nut in the channel, I just pass the bolt through one of the many oval holes along the strut, tightening the strut nut on top by hand. The safety just clips into the next available hole.

It was sold to me on the idea of being simple, not needing clamps and other assorted pipe hardware. But that was before we had a set of 8 zoom lekos and 8 fresnels donated to us. (all with clamps provided) The lekos are heavy MF'ers, very difficult to top-mount by myself. When the church wanted to replace the ceiling tiles and paint one summer, we had the advantage of their scaffold to take them down and put them back up.

I have an idea to weld the unistrut angle brackets to a 30" piece of pipe, but I'm not sure how the pipe will react to welding. The vertical strut on the wall is great for that sort of adjustability.

I also dropped a couple 10-foot lengths of thin strut (.75", I think as opposed to the 1.5" that's on the walls) just behind the curtain track, where I hang fresnels. From this strut, I don't bother with inserting the strut nut in the channel, I just pass the bolt through one of the many oval holes along the strut, tightening the strut nut on top by hand. The safety just clips into the next available hole.

It was sold to me on the idea of being simple, not needing clamps and other assorted pipe hardware. But that was before we had a set of 8 zoom lekos and 8 fresnels donated to us. (all with clamps provided) The lekos are heavy MF'ers, very difficult to top-mount by myself. When the church wanted to replace the ceiling tiles and paint one summer, we had the advantage of their scaffold to take them down and put them back up.

I have an idea to weld the unistrut angle brackets to a 30" piece of pipe, but I'm not sure how the pipe will react to welding. The vertical strut on the wall is great for that sort of adjustability.

Last edited:

JD

Well-Known Member

Two applications I liked using it:

1) Frames for Genie air-lifts. You could get a tighter grouping that was lighter in weight, easier to move, and could be left packaged.

2) ACL groups, where four fixtures would be on a bar, pre-wired. Helped keep the lamps grouped by age, and reduced set-up time as each group would only have one connector.

1) Frames for Genie air-lifts. You could get a tighter grouping that was lighter in weight, easier to move, and could be left packaged.

2) ACL groups, where four fixtures would be on a bar, pre-wired. Helped keep the lamps grouped by age, and reduced set-up time as each group would only have one connector.

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 1

- Views

- 360

- Replies

- 9

- Views

- 560

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)