So, I have had some interesting happenings over the past week of running the opening show of our season. I have had two HPL lamps in different fixtures go supernova explosively in the middle of performances. The interesting thing here is that both fixtures are on the same pipe with dedicated raceway. The raceway is actually split between two dimmer racks, though the fixtures are both on one. When the first one went, I didn't really think much of it because it happens every now and then. The second one went the next day and the damage to the lamp looked exactly the same as the previous. Unfortunately I didn't save the first lamp.

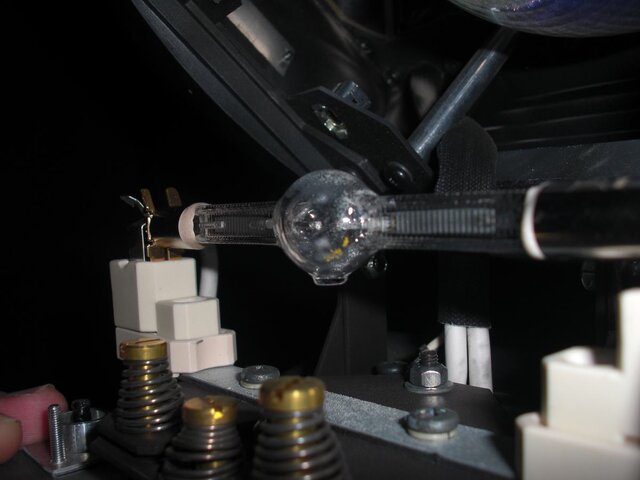

Now, on the same pipe I have two moving lights that use arc discharge lamps. Two nights ago one of those started to act up. The lamp just quit in the middle of the show and when I looked at the fixture after, it displayed a lamp error. Upon resetting the fixture, the lamp ignited and seemed to be fine. Last night we ran into the same issue and I reset the fixture in the middle of the show. The lamp re-ignited but still went out again. The lamp has 88 hours on it, it is basically brand new.

Today I decided to run some tests to diagnose the problem. I started by running though the cues in the show to see if there were any glitches or power variances that might be causing the issue. Everything worked fine. It seems that all the fans are running and everything seems normal. I have had the fixture on for a few hours now (as I write this) and have not been able to re-create the problem.

My thoughts would be to swap the lamp for one of the old ones (that never gave me any issues) for tonight's performance and see if the problem persists. If it doesn't then I suppose I would have ruled out a problem with the fixture, meaning I have a bum lamp. If the problem stays then I would assume that the issue lies with the ballast.

Thoughts? Other troubleshooting you might suggest?

EDIT: The MLs are Elation PowerSpot 700 CMYs. I have had them for four years and they have always worked nicely. I take good care of them. We even named them.

Now, on the same pipe I have two moving lights that use arc discharge lamps. Two nights ago one of those started to act up. The lamp just quit in the middle of the show and when I looked at the fixture after, it displayed a lamp error. Upon resetting the fixture, the lamp ignited and seemed to be fine. Last night we ran into the same issue and I reset the fixture in the middle of the show. The lamp re-ignited but still went out again. The lamp has 88 hours on it, it is basically brand new.

Today I decided to run some tests to diagnose the problem. I started by running though the cues in the show to see if there were any glitches or power variances that might be causing the issue. Everything worked fine. It seems that all the fans are running and everything seems normal. I have had the fixture on for a few hours now (as I write this) and have not been able to re-create the problem.

My thoughts would be to swap the lamp for one of the old ones (that never gave me any issues) for tonight's performance and see if the problem persists. If it doesn't then I suppose I would have ruled out a problem with the fixture, meaning I have a bum lamp. If the problem stays then I would assume that the issue lies with the ballast.

Thoughts? Other troubleshooting you might suggest?

EDIT: The MLs are Elation PowerSpot 700 CMYs. I have had them for four years and they have always worked nicely. I take good care of them. We even named them.

Last edited: