You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

first time I saw that before

- Thread startership

- Start date

No, that's an HMI 1200 W/S Lamp, most likely from either a VL3000 or MAC 2000.

Only about $150-$250 for a 750-hour lamp. Ship seems to have made it his life's work in determining failure modes and collecting on unused warrantied life, and keeps track of these things with more fastidiousness than anyone I know.

Only about $150-$250 for a 750-hour lamp. Ship seems to have made it his life's work in determining failure modes and collecting on unused warrantied life, and keeps track of these things with more fastidiousness than anyone I know.

Attachments

No, that's a HTI 700w/D4/60 or 75 in you photo  Possibly the 400w version otherwise. The 1.2Kw version has frosted pinches as with the 1.5Kw version which in addition to that has more rounded off pinches.

Possibly the 400w version otherwise. The 1.2Kw version has frosted pinches as with the 1.5Kw version which in addition to that has more rounded off pinches.

My default at work when not working on proto types or distros is in inspecting moving light lamps. Only got about 150 left to inspect from the last four months at about five minutes each under lit magnifying glass in studying what went wrong or the condition, than logging the replacement lamp into being installed onto the fixture etc.

Very much the first time I have ever seen the above. Think the reflector went bye bye, but it would be really cool if it were just missing a section at the center instead. Don't use moving lights, what did someone bench focus the heck out of the fixture and the lamp found reflector???

Head of moving light repair department on seeing the photo and being told what tour it came off of instantly replied - so that's why they needed a replacement reflector... Total operator error, which got into a lack of skilled labor discussion that lasted too long given it didn't have anything other than agreement or lack of solution... Still a cool first I have seen. Almost like crystals stuck to a rock if seen from the front.

Still a cool first I have seen. Almost like crystals stuck to a rock if seen from the front.

"Retail" cost noted

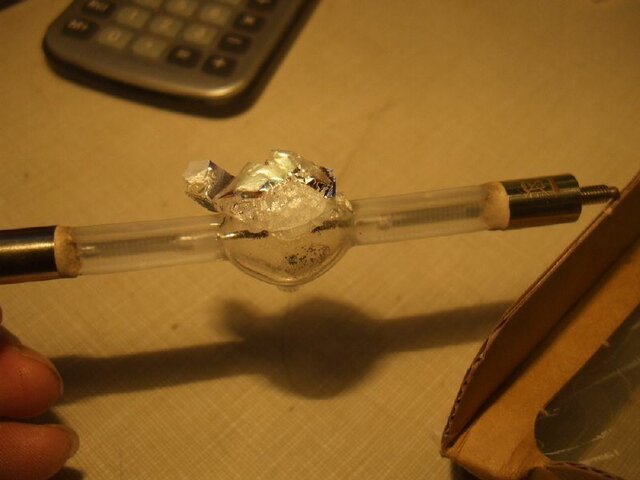

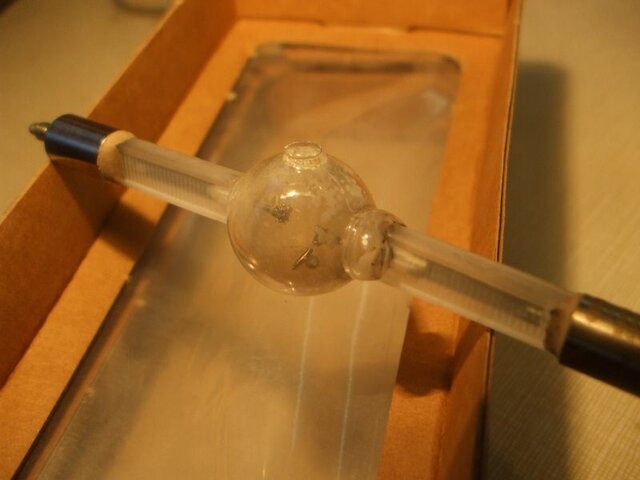

Otherwise in other firsts during the past week or two, at the moment I'm studying a end of life tapering of the electrode to the extent it melted away at the pinch and fell off, in combination with a devitrifcation phenonom on the same that happened to a lamp. -Dust particle or something on the lamp, or a deformity with the globe causes the blow up, even saw one today with it at the pinch of the globe - kind of cool. However on the electrode falling off, at 650 hours, the electrode tapering is very unusal for a 1.2K lamp even at 2,000 hours. See it a bit on a few but never on this young of a lamp. 700w lamps at about 1,400 hours sure the tapering happens. Shure also the elephantitus of the globe at times with all sorts of lamps no matter the age, never seen the two problems at once and am not sure one has to do with the other by way of how clear the lamp is. Sure seen electrodes fall off before, normally they will also show a lot of bubbles at the pinch where the electrode enters the glass - this didn't, amongst end of life clouds on the outer globe etc. This lamp was fairly well clear making it unusual to see an electrode just fall off much less tapering of it on this type of lamp at this age.

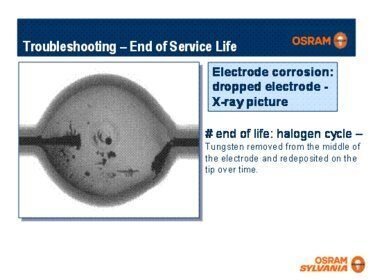

Osram rep. sent me a x-ray photo of end of life electrode tapering which seems fair enough to explain end of life but given the lamp was not at its end of life - heck I have doccumented some that last over 2,700 hours before being replaced or exploding, and this lamp was still clear instead of needing an x-ray to see the tapering of it. Such a photo didn't answer the question.

Another issue I'm looking at is like 20x out of 250 lamps on a tour suddenly need to be replaced due to fill pinch seal micro cracks - where the gas escapes out of the fill pinch at the side of the globe. Various various types of fixture - rental, ours and type, various ages of fixture and lot number of all, and lamp life from 100 to 700 hours. All seemingly after one of two stops at a local road size theater on the tour. Fixtures on the truss were struck one truss at a time and seemingly the lamps possibly dependant on how far from power or how old the ballast was in the fixture either maintained an arc for a while than doused or maintained an arc but not sufficient to retain the heat of the tungsten particles sufficient that they got re-deposited on the electrodes and instead were attacking the fill pinch to the extent that some had gas failures. All lamps no matter age or lot number, including one of another brand had various amouts of attack on the fill pinch from just silver crusties building up near it and electrodes bare to a total gas failure with gas leak and silver globe with yellow rings. Much I think dependant on the ballast and power to it.

Thinking these were perhaps on the last truss arcs were struck on - after the rest had arcs struck and there was a slight brown out or voltage drop at the theater given all the fixtures running in it sufficient the fixtures did their best to maintain arcs but couldn't. This either at misc. locations with older ballasts or on the last truss or two. Fairly rare for a fill pinch failure, never seen it before that almost 10% of a tours fixtures within a month all get replaced for the same rare condition. This especially with such a range over the first 200 hours, different lot numbers and range in extent of the failure from just silver crusties but no failure to full silver snowball with yellow axial rings.

Still working on forming up this noting and perhaps comparing what fixture had a bad lamp with this condition during this period of time, and where they were on the plot or the age of the ballast having that lamp. Could be interesting even if most involved with the show or in general don't find any links or see anything unusual. No generators were used and those changing the lamps didn't note anything different about the lamps they were replacing of course in wondering why so many lamps at once failed in a less than normal looking failure. This much less if my theory is correct, why so many fixtures on one or two truss's went all at once.

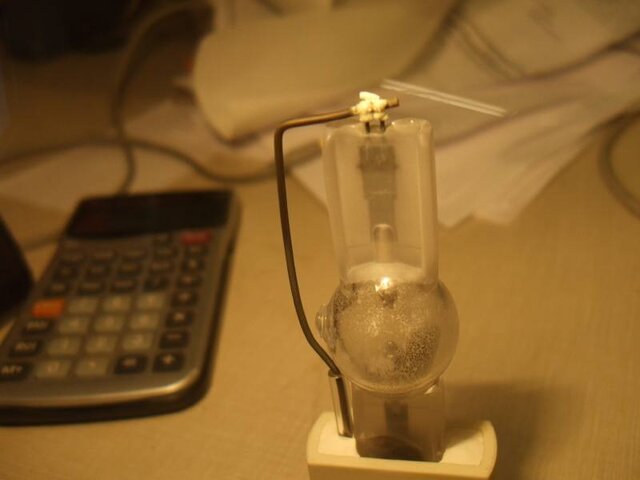

Photo enclosed wasn't one of them - shows the yellow rings and a lamp that let the gas out about mid-way thru doing so before it stopped with its arc. Obviously it also had a bad fixture lamp socket that was related or perhaps not. Still a photo of what I'm talking about. And the electrode tapering from the other lamp.

My default at work when not working on proto types or distros is in inspecting moving light lamps. Only got about 150 left to inspect from the last four months at about five minutes each under lit magnifying glass in studying what went wrong or the condition, than logging the replacement lamp into being installed onto the fixture etc.

Very much the first time I have ever seen the above. Think the reflector went bye bye, but it would be really cool if it were just missing a section at the center instead. Don't use moving lights, what did someone bench focus the heck out of the fixture and the lamp found reflector???

Head of moving light repair department on seeing the photo and being told what tour it came off of instantly replied - so that's why they needed a replacement reflector... Total operator error, which got into a lack of skilled labor discussion that lasted too long given it didn't have anything other than agreement or lack of solution...

"Retail" cost noted

Otherwise in other firsts during the past week or two, at the moment I'm studying a end of life tapering of the electrode to the extent it melted away at the pinch and fell off, in combination with a devitrifcation phenonom on the same that happened to a lamp. -Dust particle or something on the lamp, or a deformity with the globe causes the blow up, even saw one today with it at the pinch of the globe - kind of cool. However on the electrode falling off, at 650 hours, the electrode tapering is very unusal for a 1.2K lamp even at 2,000 hours. See it a bit on a few but never on this young of a lamp. 700w lamps at about 1,400 hours sure the tapering happens. Shure also the elephantitus of the globe at times with all sorts of lamps no matter the age, never seen the two problems at once and am not sure one has to do with the other by way of how clear the lamp is. Sure seen electrodes fall off before, normally they will also show a lot of bubbles at the pinch where the electrode enters the glass - this didn't, amongst end of life clouds on the outer globe etc. This lamp was fairly well clear making it unusual to see an electrode just fall off much less tapering of it on this type of lamp at this age.

Osram rep. sent me a x-ray photo of end of life electrode tapering which seems fair enough to explain end of life but given the lamp was not at its end of life - heck I have doccumented some that last over 2,700 hours before being replaced or exploding, and this lamp was still clear instead of needing an x-ray to see the tapering of it. Such a photo didn't answer the question.

Another issue I'm looking at is like 20x out of 250 lamps on a tour suddenly need to be replaced due to fill pinch seal micro cracks - where the gas escapes out of the fill pinch at the side of the globe. Various various types of fixture - rental, ours and type, various ages of fixture and lot number of all, and lamp life from 100 to 700 hours. All seemingly after one of two stops at a local road size theater on the tour. Fixtures on the truss were struck one truss at a time and seemingly the lamps possibly dependant on how far from power or how old the ballast was in the fixture either maintained an arc for a while than doused or maintained an arc but not sufficient to retain the heat of the tungsten particles sufficient that they got re-deposited on the electrodes and instead were attacking the fill pinch to the extent that some had gas failures. All lamps no matter age or lot number, including one of another brand had various amouts of attack on the fill pinch from just silver crusties building up near it and electrodes bare to a total gas failure with gas leak and silver globe with yellow rings. Much I think dependant on the ballast and power to it.

Thinking these were perhaps on the last truss arcs were struck on - after the rest had arcs struck and there was a slight brown out or voltage drop at the theater given all the fixtures running in it sufficient the fixtures did their best to maintain arcs but couldn't. This either at misc. locations with older ballasts or on the last truss or two. Fairly rare for a fill pinch failure, never seen it before that almost 10% of a tours fixtures within a month all get replaced for the same rare condition. This especially with such a range over the first 200 hours, different lot numbers and range in extent of the failure from just silver crusties but no failure to full silver snowball with yellow axial rings.

Still working on forming up this noting and perhaps comparing what fixture had a bad lamp with this condition during this period of time, and where they were on the plot or the age of the ballast having that lamp. Could be interesting even if most involved with the show or in general don't find any links or see anything unusual. No generators were used and those changing the lamps didn't note anything different about the lamps they were replacing of course in wondering why so many lamps at once failed in a less than normal looking failure. This much less if my theory is correct, why so many fixtures on one or two truss's went all at once.

Photo enclosed wasn't one of them - shows the yellow rings and a lamp that let the gas out about mid-way thru doing so before it stopped with its arc. Obviously it also had a bad fixture lamp socket that was related or perhaps not. Still a photo of what I'm talking about. And the electrode tapering from the other lamp.

Attachments

Last edited:

maybe i should start sending all of my dead lamps to you for you to investigate. My normalism is hey that lamp is dim (msr700sa's) check fixture hours 600 hrs lamp goes in box marked as used with 600 hrs and new lamp goes it. Thats about it. I have one in which the base blew up and one in which the glass half way up poped in half. Cybers get new lamps normally when they are extremely dim or they go boom. I do have one interesting lamp laying in my garage i will post a pic on to see what you think.

Post the photo away. On Mac 2K lamps upon bet or normal, I can normally estimate how many hours the lamp has been used to within say 50 hours plus or minus up to 800 and there abouts of 200 after that. Not perfect on the study of lamps at this point but I have inspected within say close to ten thousand moving light lamps over my last almost ten years now.

On the other hand, sending your bad lamps to me would be a bad idea.... did you know my last estimate for a 55gal drum full of arc source moving light lamps is going to cost me like $1,000.00 per drum to dispose of? Just filled up my third drum.

600 hours for a MSR 700SA could be dim but shouldn’t be dim yet. That’s right on the line of living up to - I still say it should be 750hr lamp life but depending on the literature it’s 500 hour, and even with that after 500 or like 300 hours it’s no longer warranty in returning it. Still, given 600 hours of use, if the lamp were still sufficiently clear, I would stick it into another instrument if not a newer one and eek out if possible in bench focus after an hour of burn in another couple hundred hours. 700SA lamps seem for the most part to work or not - very high output and temperamental lamps often in either working or not, but possible to save if still in good shape into another fixture. Otherwise write it off for the cost of doing business.

Should you want post away and or contact me off line and I’ll direct contact you in with photos what is wrong with the lamp as best possible or at least what to watch for.

Posted is 22 out of like 27 of the above 10% of the shows lamps “one stop on a tour bad lamps in a normally only like 2% of lamps typically have this rare problem failure.”

This an a few other things I saw in the recent week including never having seen a frosty corrosion on the welded lead in wires before. A week of firsts for me in new stuff noticed.

Note the range of silver crusties around the fill pinch to the ones with the grey clouds with yellow edges to the silver snowball ones with yellow streaks. As with the above photo, beyond seeing silver, seeing yellow a yellow ring on the edge of the silver or grey clouding means gas has been getting out normally. Also a lamp to be careful of because gas has been getting out. Often one can follow the silver cloud and rings to see where the failure was.

On lamp age, one basically counts the bubbles. On seeing enough lamps that you are told the age of, one can at some point estimate on other lamps based on this how many hours any moving light lamp has been in use if one can see the electrode bubbles - as if counting them. ON the other hand crusties, inner pinch bubbles, clouding, frost, snow etc. also helps indicate as a secondary thing especially if your electrode doesn't have bubbles and especially if it seems blackened - bubbles sucked off the electrode and say towards a hole in the globe.

All details about lamp failure and lots of concepts or how it fails. What's posted in this post hopefully is really really rare to see and if you do you should start asking questions about what caused it. What's a good thing to see is either a lamp at the rated life replaced or if not what's called a snowball. Simply the globe of the lamp is all white and seems as if a snowball. That's normally what you see or rate a lamp on to the extent of in achieving. hmm, a bit frosty, verses light vapor clouds forming, verses light snow, verses light clouds forming, verses etc. in all classifications getting worse as the lamp ages.

Also of note, the silver cloud or crusties about the fill pinch and or globe/pinch areas are normal within the first hundred hours. Either within the first 200 hours, such attack of the tungsten and chemicals not being burnt are going to make a micro crack in the glass or they normally after that - burn in period won't be a problem. Proper burn in time and voltage are very important. Anyway, details... lots of them on lamp study.

On the other hand, sending your bad lamps to me would be a bad idea.... did you know my last estimate for a 55gal drum full of arc source moving light lamps is going to cost me like $1,000.00 per drum to dispose of? Just filled up my third drum.

600 hours for a MSR 700SA could be dim but shouldn’t be dim yet. That’s right on the line of living up to - I still say it should be 750hr lamp life but depending on the literature it’s 500 hour, and even with that after 500 or like 300 hours it’s no longer warranty in returning it. Still, given 600 hours of use, if the lamp were still sufficiently clear, I would stick it into another instrument if not a newer one and eek out if possible in bench focus after an hour of burn in another couple hundred hours. 700SA lamps seem for the most part to work or not - very high output and temperamental lamps often in either working or not, but possible to save if still in good shape into another fixture. Otherwise write it off for the cost of doing business.

Should you want post away and or contact me off line and I’ll direct contact you in with photos what is wrong with the lamp as best possible or at least what to watch for.

Posted is 22 out of like 27 of the above 10% of the shows lamps “one stop on a tour bad lamps in a normally only like 2% of lamps typically have this rare problem failure.”

This an a few other things I saw in the recent week including never having seen a frosty corrosion on the welded lead in wires before. A week of firsts for me in new stuff noticed.

Note the range of silver crusties around the fill pinch to the ones with the grey clouds with yellow edges to the silver snowball ones with yellow streaks. As with the above photo, beyond seeing silver, seeing yellow a yellow ring on the edge of the silver or grey clouding means gas has been getting out normally. Also a lamp to be careful of because gas has been getting out. Often one can follow the silver cloud and rings to see where the failure was.

On lamp age, one basically counts the bubbles. On seeing enough lamps that you are told the age of, one can at some point estimate on other lamps based on this how many hours any moving light lamp has been in use if one can see the electrode bubbles - as if counting them. ON the other hand crusties, inner pinch bubbles, clouding, frost, snow etc. also helps indicate as a secondary thing especially if your electrode doesn't have bubbles and especially if it seems blackened - bubbles sucked off the electrode and say towards a hole in the globe.

All details about lamp failure and lots of concepts or how it fails. What's posted in this post hopefully is really really rare to see and if you do you should start asking questions about what caused it. What's a good thing to see is either a lamp at the rated life replaced or if not what's called a snowball. Simply the globe of the lamp is all white and seems as if a snowball. That's normally what you see or rate a lamp on to the extent of in achieving. hmm, a bit frosty, verses light vapor clouds forming, verses light snow, verses light clouds forming, verses etc. in all classifications getting worse as the lamp ages.

Also of note, the silver cloud or crusties about the fill pinch and or globe/pinch areas are normal within the first hundred hours. Either within the first 200 hours, such attack of the tungsten and chemicals not being burnt are going to make a micro crack in the glass or they normally after that - burn in period won't be a problem. Proper burn in time and voltage are very important. Anyway, details... lots of them on lamp study.

Attachments

Overall concept for where I work is that I track every lamp costing us between about $73.00 and $2.4K per lamp in stock. That’s a good thing but with over 16,000 lamps tracked (most in their demise but still on the computer tracking), I have a good data base for studying lamp failure tendancies, lot number problems, brand problems and other stuff. Also, I can even tell should a fixture serial number be removed, what serial number that fixture is by way of the lamp in it. This beyond being able with some experience being able to save money on re-testing at times twice or a third time once rejected as being dim or off in color temperature, if it still looks good to me, trying it in another fixture and much of the time it works out just fine with a different ballast. This beyond say about a 1% return of lamps for reimbursement rate. Lamp is listed for X amount of lamp hours, if not operator error and if you can document the history of the lamp and confirm the lamp being dim, failing before 2/3's of its expected lamp life, that’s a lamp that goes back to who sold it to you. A few months later after traveling to Europe for inspection, and if you have a valid claim on it you either get a replacement lamp or a refund on it. That’s SOP for expensive or any lamps as long as you can track them properly. Know of some companies sister to us that have a bucket of good lamps and a bucket of dim lamps that depending on what profile the show is they are prepping them for they choose the lamps for. Ain’t how we work and in doing lamp tracking we get back given around 2,500 moving light lamps bought per year, around 300 to 600 lamps worth of refund per year by way of tracking each lamp as an individual lamp.

Takes a very good organization of course and I constantly curse or yell at the free lance and or others of staff that don’t when changing lamps just accurately fill out like five lines of text on each replacement lamp box because in a realistic sense - for each moving light lamp without it’s pedigree, that’s one day rate of an employee less. Those wishing there were more help to prep a show or out on a show to me I simply note how much we waste a year in lamps in comparison to that extra body’s salary per year.

Just five, now six lines of text to fill out on each box. Each box when recieving it gets inspected for quality and it’s serial number gets noted on the outside of the box before the lamp sticker gets placed on the box. Each new lamp is than logged into the computer with the date of arrival, who it was bought from and what purchase order it was bought under. A sticker or three is than placed on the box. First sticker - them Osram stickers if Osram that come with the lamps - something like “Caution Shark XS inside”. Any sticker that says caution is good for me in hopefully helping prevent the broken on install lamps percentage. And if just left in the box, tech people are like kids, we would start seeing the sickers everywhere - a note the Osram rep. in me complaining about the stickers seemed to take some “I Know” humor about. Second sticker is one I have fought Osram and Philips about, one I pay to have made for me. It’s the lamp wattage. Last week I had our first 1.2Kw Mac 2K lamp installed into a Mac 2K XB fixture. This as opposed to about a year or two ago the constant install of Mac 700 lamps installed into Mac 2K fixtures. Simple 1"x3" stickers placed on each box given all boxes are the same and the actual lamp description is in small print helps tremendously to prevent the wrong lamp from being money down the drain after it fails at about 400 hours when in the wrong fixture. This or marking the boxes with high lighter colors or sharpee wattage of lamp type stuff helps prevent people from pulling the wrong lamp. Same issue with 1.2Kw verses 2Kw FastFit lamps, really difficult given the same boxes to prevent.

Third sticker is the world for me in tracking lamps. Just five lines of text to fill out, yet beyond Ronald McDonald having changed the lamp at times as if a joke, amazing how few people in seeing five blanks to fill out either attempt to fill out any, or just leave out a few blanks, even one. Ok, if the lamps’ in the box - assuming they have any lamp in the box or just one in the box, also problems at times, I can get the serial number off that lamp as needed so that’s the least important blank to fill in. Lamp installed into the fixture is already marked on the box so what lamp is removed from the fixture which is now in the box is a little less important for someone to put on the box. But on the other hand, if someone is changing say one lamp and I’m typing into the computer say sixty lamps per day, there is a big difference in needing to look at the small print for those with one instead of one with sixty say to look at.

Still that’s the least important line to fill out and one that don’t anger me because it won’t effect warranty on the lamp. I can fill that one in as needed.

Other lines are date - date of lamp change, just sent an Email out to someone who put as date 12/23. Hmm, it’s 12/18 and I have been sitting on these lamps for a few weeks now. Do you not even know if it’s two days before Christmas? Still I was by him at least filling in that, assume he meant 11/23 as opposed to others that don’t and I now have no idea of when not just the lamp was removed, but when the new lamp was installed. Simple as a date - busy, can you fill such a line in later perhaps??? Same with who changed the lamp. If a problem, it’s good to be able to contact them. Took a few years but even MR. IATSE #2 finally started filling out his lamp sheet, name of person that changed the lamp is still prefered but what ever the case, it’s a blank to fill out, what’s difficult about that? Get boxes back with “bad” written across this form. Gee, that’s helpful.

Next line after name is reason for replacement. “I said so...” yea, that’s helpful. Two “dim’s” or a dim and a brown equal a lamp sent back after being tried twice for a full refund on the lamp if under 2/3's its expected lamp life - within reason and not if for other reasons. I average about 100% refunds these days but have a few thousand lamps under the belt inspected for submitting such lamps. Still a lamp confirmed to be bad not in just one fixture but two and it’s probably bad. Ronald McDonald saying he says so’ means we start over on the lamp at best if not throw out any chance in being honest with a valid lamp history of why it was rejected and throwing the money down the hole because someone was being funny at the expense of a day rate of someone’s salary per day.

Every lamp for me means one person’s day rate in pay and I inspect them with that in mind.

So, dim, brown, yellow, etc. help in describing why the lamp on seeing it in use was replaced is helpful. Otherwise at times when first the fixtures are opened up for cleaning before bench focused in fixtures one to another, such weather conditions about what the globe looks like is acceptable if later in the lamp life. “Snowball” is common even if just cloudy, frosty and snowstorm for what the globe looks like. Leave the weather forcast to me but often those saying such stuff for reason for rejection are fine in saying so based on the concept that such stuff on the globe will prevent light from getting out or graphically light from getting out as a small pinpoint source of light. Reason for replacement in those instances is valid - looked at the lamp and it’s looking like it won’t be around long in other words. Another valid for me “reason for replacement” reason is “Hours.” Got a few tours that have been out for over a year now and might be out for a few more years without return. They are doing good in replacing 750 hour rated lamps at around 800 to 1200 hours by way of the realistic extent the lamps will life and group replacement of all of them. By that time, the lamps are trash, and on long tours lamps often do last long beyond their expected lamp life when left alone or with a long tour or install persay one don’t realize the drop in output as much overall with lamp life.

So reason for replacement for me is a good thing of note in sending the lamps back if under 2/3 lamp life, and otherwise what’s noted about the lamp. Beyond that next is details often very important.

Frequently fixtures show up to rehearsal and never get to the shop. I don’t get the ability often for a new fixture as I like to for the initial lamps install into the computer that lamp’s serial number with seller of the lamp, date of delivery, fixture serial number for us as with manufacturer bar code, and purchase order. Often it’s “unknown install” and a lot of ??? for other stuff. Them lamps unless I do a lot of computer work have no chance of warranty replacement. So, another line on the sticker on each replacement lamp is fixture serial number. Not the manufacturer serial number/bar code, our serial number that’s a little less extreme in numbers. If I get the lamp/fixture list for new fixtures before the show leaves I can if barcode number figure out a fixture number otherwise, but if not filled in or better yet if someone says say A2 for what fixture number that was on the plot... that’s useless to me and often a reason I cannot send back a lamp.

Granted people are at times hanging 40' up in the air up side down in changing lamps - no doubt always doing so, or the people changing the lamps those supervising them are either intimidated into not asking too many questions of or too lazy as the case of our shop manager it would seem amongst the worst in filling out the lamp data... what ever the case, if I have info on a past lamp install in the computer, often within a few minutes I can figure out what fixture it is in. Otherwise as with above, it’s either a “lost” lamp no longer valid return or something with link to up to three past lamps not valid but at least I can fill in the black hole for some day as to what fixture they were assigned to. Shouldn’t be that difficult but often it is.

Than the most important question - lamp hours. You know, some older fixtures don’t track lamp hours and that’s fair enough, but if you as a “professional” are doing your job, you are resetting the lamp hours on the fixture anyway so there is no reason why one would not at very least be able to fill this blank in. Heck, for some xenon lamps to get a warranty claim on them I also need strikes and if not burst modes on them, for a HMI lamp, it is still just lamp hours I need. What’s so difficult about filling this most crucial of all blanks? Often the most not filled in blank but often also even if not for return the most telling about the fixture. Going thru a lot of lamps? Could it be a lot number or perhaps the fixture? How to track if not for lamp hours and a fixture history?

Sure, I can estimate the amount of hours a lamp has been in use but it’s not valid for return. Above all else lamp hours as tracked by the fixture and you get anyway in doing your job by way of resetting the lamp counter you have anyway. Yet frequently the only thing left off the tag to fill in meaning a lamp that cannot be returned.

Added to this recently another just blank to “X” off for six things now to fill out. “Lamp Socket Changed?” Wouldn’t believe the amount of lamps I get back with failures due to bad fixture lamp sockets, and in seeing them but being back logged I don’t have a chance to ask if they also changed the lamp socket. Some crew chiefs in me sending e-mails after the second or third bad lamp due to a bad socket in a fixture asking about the fixture automatically tell me if socket changed, others it does take a total melt down of the socket before they change the socket - this in wasting a few hundred dollars worth of lamps before they note the condition of the socket.

My job to inspect lamps for cause of failure, one would think that of those changing the lamps also in doing their job, but not the case in the field it would seem in often once a bad fixture socket it often not changed until about the second or third lamp past when it’s bad. With the new line to fill out, hopefully at last as with “lamp counter reset” the person changing the lamp and filling out the sticker (one with our company name and phone number on it also, plus “return all bad lamps”) will if for a moment pay attention to the lamp socket that’s 1/5 the price of a lamp.

Anyway, a simple tag to fill out on each replacement lamp box. Simple enough to fill out or within reason fill out as best possible within limited amounts of not being able to fully. Constant battle for me and the largest thing that stands between a bad lamp in the trash and one that can get returned for credit. Just a few lines of text that lets me fill out that lamps’ history on the computer.

For those lamps without serial numbers, between graphite pencil and engraving tool, every lamp that goes out my door has a unique serial number or I don’t by that brand of lamp. Saving money at times aint’ worth the effort at others in attempting to track them.

Takes a very good organization of course and I constantly curse or yell at the free lance and or others of staff that don’t when changing lamps just accurately fill out like five lines of text on each replacement lamp box because in a realistic sense - for each moving light lamp without it’s pedigree, that’s one day rate of an employee less. Those wishing there were more help to prep a show or out on a show to me I simply note how much we waste a year in lamps in comparison to that extra body’s salary per year.

Just five, now six lines of text to fill out on each box. Each box when recieving it gets inspected for quality and it’s serial number gets noted on the outside of the box before the lamp sticker gets placed on the box. Each new lamp is than logged into the computer with the date of arrival, who it was bought from and what purchase order it was bought under. A sticker or three is than placed on the box. First sticker - them Osram stickers if Osram that come with the lamps - something like “Caution Shark XS inside”. Any sticker that says caution is good for me in hopefully helping prevent the broken on install lamps percentage. And if just left in the box, tech people are like kids, we would start seeing the sickers everywhere - a note the Osram rep. in me complaining about the stickers seemed to take some “I Know” humor about. Second sticker is one I have fought Osram and Philips about, one I pay to have made for me. It’s the lamp wattage. Last week I had our first 1.2Kw Mac 2K lamp installed into a Mac 2K XB fixture. This as opposed to about a year or two ago the constant install of Mac 700 lamps installed into Mac 2K fixtures. Simple 1"x3" stickers placed on each box given all boxes are the same and the actual lamp description is in small print helps tremendously to prevent the wrong lamp from being money down the drain after it fails at about 400 hours when in the wrong fixture. This or marking the boxes with high lighter colors or sharpee wattage of lamp type stuff helps prevent people from pulling the wrong lamp. Same issue with 1.2Kw verses 2Kw FastFit lamps, really difficult given the same boxes to prevent.

Third sticker is the world for me in tracking lamps. Just five lines of text to fill out, yet beyond Ronald McDonald having changed the lamp at times as if a joke, amazing how few people in seeing five blanks to fill out either attempt to fill out any, or just leave out a few blanks, even one. Ok, if the lamps’ in the box - assuming they have any lamp in the box or just one in the box, also problems at times, I can get the serial number off that lamp as needed so that’s the least important blank to fill in. Lamp installed into the fixture is already marked on the box so what lamp is removed from the fixture which is now in the box is a little less important for someone to put on the box. But on the other hand, if someone is changing say one lamp and I’m typing into the computer say sixty lamps per day, there is a big difference in needing to look at the small print for those with one instead of one with sixty say to look at.

Still that’s the least important line to fill out and one that don’t anger me because it won’t effect warranty on the lamp. I can fill that one in as needed.

Other lines are date - date of lamp change, just sent an Email out to someone who put as date 12/23. Hmm, it’s 12/18 and I have been sitting on these lamps for a few weeks now. Do you not even know if it’s two days before Christmas? Still I was by him at least filling in that, assume he meant 11/23 as opposed to others that don’t and I now have no idea of when not just the lamp was removed, but when the new lamp was installed. Simple as a date - busy, can you fill such a line in later perhaps??? Same with who changed the lamp. If a problem, it’s good to be able to contact them. Took a few years but even MR. IATSE #2 finally started filling out his lamp sheet, name of person that changed the lamp is still prefered but what ever the case, it’s a blank to fill out, what’s difficult about that? Get boxes back with “bad” written across this form. Gee, that’s helpful.

Next line after name is reason for replacement. “I said so...” yea, that’s helpful. Two “dim’s” or a dim and a brown equal a lamp sent back after being tried twice for a full refund on the lamp if under 2/3's its expected lamp life - within reason and not if for other reasons. I average about 100% refunds these days but have a few thousand lamps under the belt inspected for submitting such lamps. Still a lamp confirmed to be bad not in just one fixture but two and it’s probably bad. Ronald McDonald saying he says so’ means we start over on the lamp at best if not throw out any chance in being honest with a valid lamp history of why it was rejected and throwing the money down the hole because someone was being funny at the expense of a day rate of someone’s salary per day.

Every lamp for me means one person’s day rate in pay and I inspect them with that in mind.

So, dim, brown, yellow, etc. help in describing why the lamp on seeing it in use was replaced is helpful. Otherwise at times when first the fixtures are opened up for cleaning before bench focused in fixtures one to another, such weather conditions about what the globe looks like is acceptable if later in the lamp life. “Snowball” is common even if just cloudy, frosty and snowstorm for what the globe looks like. Leave the weather forcast to me but often those saying such stuff for reason for rejection are fine in saying so based on the concept that such stuff on the globe will prevent light from getting out or graphically light from getting out as a small pinpoint source of light. Reason for replacement in those instances is valid - looked at the lamp and it’s looking like it won’t be around long in other words. Another valid for me “reason for replacement” reason is “Hours.” Got a few tours that have been out for over a year now and might be out for a few more years without return. They are doing good in replacing 750 hour rated lamps at around 800 to 1200 hours by way of the realistic extent the lamps will life and group replacement of all of them. By that time, the lamps are trash, and on long tours lamps often do last long beyond their expected lamp life when left alone or with a long tour or install persay one don’t realize the drop in output as much overall with lamp life.

So reason for replacement for me is a good thing of note in sending the lamps back if under 2/3 lamp life, and otherwise what’s noted about the lamp. Beyond that next is details often very important.

Frequently fixtures show up to rehearsal and never get to the shop. I don’t get the ability often for a new fixture as I like to for the initial lamps install into the computer that lamp’s serial number with seller of the lamp, date of delivery, fixture serial number for us as with manufacturer bar code, and purchase order. Often it’s “unknown install” and a lot of ??? for other stuff. Them lamps unless I do a lot of computer work have no chance of warranty replacement. So, another line on the sticker on each replacement lamp is fixture serial number. Not the manufacturer serial number/bar code, our serial number that’s a little less extreme in numbers. If I get the lamp/fixture list for new fixtures before the show leaves I can if barcode number figure out a fixture number otherwise, but if not filled in or better yet if someone says say A2 for what fixture number that was on the plot... that’s useless to me and often a reason I cannot send back a lamp.

Granted people are at times hanging 40' up in the air up side down in changing lamps - no doubt always doing so, or the people changing the lamps those supervising them are either intimidated into not asking too many questions of or too lazy as the case of our shop manager it would seem amongst the worst in filling out the lamp data... what ever the case, if I have info on a past lamp install in the computer, often within a few minutes I can figure out what fixture it is in. Otherwise as with above, it’s either a “lost” lamp no longer valid return or something with link to up to three past lamps not valid but at least I can fill in the black hole for some day as to what fixture they were assigned to. Shouldn’t be that difficult but often it is.

Than the most important question - lamp hours. You know, some older fixtures don’t track lamp hours and that’s fair enough, but if you as a “professional” are doing your job, you are resetting the lamp hours on the fixture anyway so there is no reason why one would not at very least be able to fill this blank in. Heck, for some xenon lamps to get a warranty claim on them I also need strikes and if not burst modes on them, for a HMI lamp, it is still just lamp hours I need. What’s so difficult about filling this most crucial of all blanks? Often the most not filled in blank but often also even if not for return the most telling about the fixture. Going thru a lot of lamps? Could it be a lot number or perhaps the fixture? How to track if not for lamp hours and a fixture history?

Sure, I can estimate the amount of hours a lamp has been in use but it’s not valid for return. Above all else lamp hours as tracked by the fixture and you get anyway in doing your job by way of resetting the lamp counter you have anyway. Yet frequently the only thing left off the tag to fill in meaning a lamp that cannot be returned.

Added to this recently another just blank to “X” off for six things now to fill out. “Lamp Socket Changed?” Wouldn’t believe the amount of lamps I get back with failures due to bad fixture lamp sockets, and in seeing them but being back logged I don’t have a chance to ask if they also changed the lamp socket. Some crew chiefs in me sending e-mails after the second or third bad lamp due to a bad socket in a fixture asking about the fixture automatically tell me if socket changed, others it does take a total melt down of the socket before they change the socket - this in wasting a few hundred dollars worth of lamps before they note the condition of the socket.

My job to inspect lamps for cause of failure, one would think that of those changing the lamps also in doing their job, but not the case in the field it would seem in often once a bad fixture socket it often not changed until about the second or third lamp past when it’s bad. With the new line to fill out, hopefully at last as with “lamp counter reset” the person changing the lamp and filling out the sticker (one with our company name and phone number on it also, plus “return all bad lamps”) will if for a moment pay attention to the lamp socket that’s 1/5 the price of a lamp.

Anyway, a simple tag to fill out on each replacement lamp box. Simple enough to fill out or within reason fill out as best possible within limited amounts of not being able to fully. Constant battle for me and the largest thing that stands between a bad lamp in the trash and one that can get returned for credit. Just a few lines of text that lets me fill out that lamps’ history on the computer.

For those lamps without serial numbers, between graphite pencil and engraving tool, every lamp that goes out my door has a unique serial number or I don’t by that brand of lamp. Saving money at times aint’ worth the effort at others in attempting to track them.

By way of the new line, I’ll if filled out for lamp socket changed, be able to stop sending emails to crew chiefs in asking about clearly bad to me lamps due to lamp socket in failure - assuming they fill out the new box and give a thought now in being helped to inspecting the lamps/sockets on removal, and give note to the moving light repair department when I get wind of a socket change so they no doubt also in their own fixture history tracking can further track lamp socket changes.

Knowing there is X amount of recommended lamp hours on a lamp socket/base it’s not realistic those in the field will know how many lamp changes or hours that lampholder has been in use. This for field use, new line item will hopefully at least help those in the field let those back at home know what’s going on with the fixtures and lamps we are charged with and play a big role in our later exposure to the gear.

As said, I’m sure the moving lights repair department has just as much computer tracking of the history of each and every fixture we own or service. I’m told of a long trail of paperwork for warranty repair work so it’s gotta be extensive. Lots of fixtures demands that but a thought being that anyone can have a similar system of repair and lamps for their own gear which while it would take some computer set up and extra time, would save money in the long run for warranty or resale stuff in tracking history. This much less could form some way to pre-plan repair, lamps and other budget expenses. Bit of work on the computer, a lineage of all gear means what you own often stays yours if you can account for it after a show or pre-planned repair when there is time in forcasting what’s needed.

Anyway, repair and lamps at this point are not linked other than in separate programs. Smaller scale operations, one could link lots of stuff and save lots of money, or at least with lamp/fixture history be able to assure that if not your fault you get back your investment. A computer person on the crew might be the first abused but these days it’s also the person next to the designer and ME that brings back the best return profit for investment.

Ladder climbers, ME, designer or computer person for end career because you can’t just sit on a ladder for your career. What next very important if not gas station attendant.

Knowing there is X amount of recommended lamp hours on a lamp socket/base it’s not realistic those in the field will know how many lamp changes or hours that lampholder has been in use. This for field use, new line item will hopefully at least help those in the field let those back at home know what’s going on with the fixtures and lamps we are charged with and play a big role in our later exposure to the gear.

As said, I’m sure the moving lights repair department has just as much computer tracking of the history of each and every fixture we own or service. I’m told of a long trail of paperwork for warranty repair work so it’s gotta be extensive. Lots of fixtures demands that but a thought being that anyone can have a similar system of repair and lamps for their own gear which while it would take some computer set up and extra time, would save money in the long run for warranty or resale stuff in tracking history. This much less could form some way to pre-plan repair, lamps and other budget expenses. Bit of work on the computer, a lineage of all gear means what you own often stays yours if you can account for it after a show or pre-planned repair when there is time in forcasting what’s needed.

Anyway, repair and lamps at this point are not linked other than in separate programs. Smaller scale operations, one could link lots of stuff and save lots of money, or at least with lamp/fixture history be able to assure that if not your fault you get back your investment. A computer person on the crew might be the first abused but these days it’s also the person next to the designer and ME that brings back the best return profit for investment.

Ladder climbers, ME, designer or computer person for end career because you can’t just sit on a ladder for your career. What next very important if not gas station attendant.

Let the above be a lesson to anyone considering the purchase of moving lights, and remember that this thread is focused only on lamps, and barely touches on all the other maintenance involved. If one rents rather than buys, all this becomes Ship's problem, and if a light breaks, one simply calls the shop to send another.

Similar threads

- Replies

- 3

- Views

- 2K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)